BORON NITRIDE, the THERMAL CONDUCTOR

Thermal conductivity is a measurement of how well heat moves from one material to another, or even when an object comes into contact with the air on a cold winter day. The higher the thermal conductivity typically means that materials like Boron Nitride will be good insulators and keep us warm during those frigid winters. Materials with low thermal conductivities are typically porous materials like wool that hold less warm air.

Boron Nitride provides Thermal Conductivity

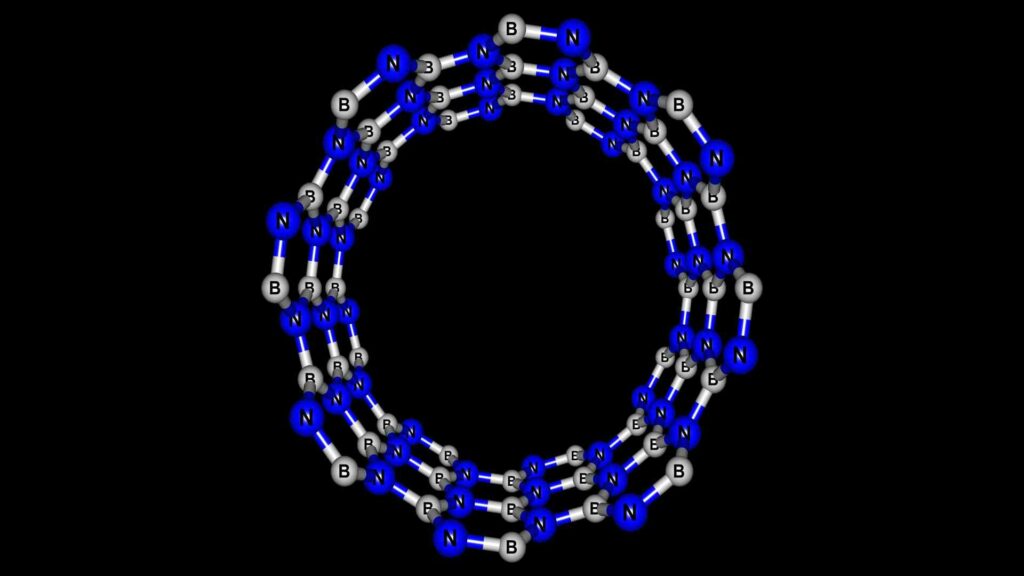

Boron nitride, also known as “white graphite,” is a semiconductor material that conducts electricity. It is chemically inert and electrically insulating with no bandgap in the bulk phase that would allow it to emit light when excited by an energy source. As such, boron nitride cannot be used to fabricate transistors or LEDs on its own. However, because of its excellent thermal conductivity properties, layers of boron nitride are often added onto other materials like silicon carbide (SiC) for use in high-efficiency power devices like thermoelectric cooler packages (TECs).

The theory on hexagonal boron nitride nanoribbons is that their thermal conductivity can be as high as 1700-2000 W/ (m•K) which would approach the same order of magnitude for graphene and could be comparable to what theoretical calculations project about graphene nanoribbons. What’s more, BNNRs are anisotropic in terms of heat output meaning they transport it differently depending on whether or not their edges zigzag or armchair shaped. This means that at room temperature the thermal conductivity from a zigzagged edge will 20% higher than one with an armchair shape.

Boron Nitride Reinforced Polyethylene Composites

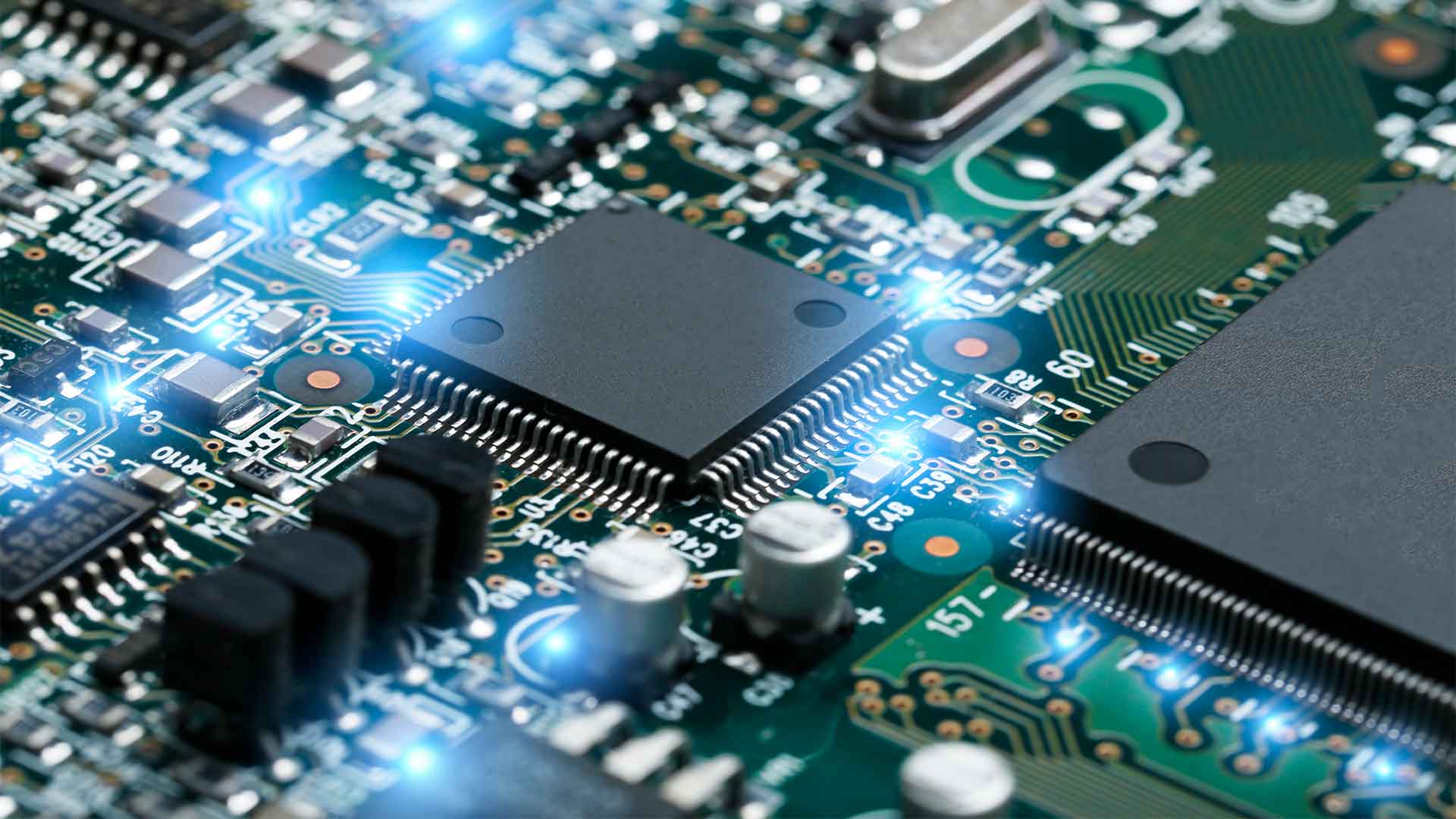

Polymer composites with high thermal conductivity, low coefficient of thermal expansion (CTE), and high electrical resistance have been a recent development in the market. The importance of these properties is associated with their use as circuit boards for appliances such as computers or refrigerators that require heat exchangers where they are needed most. As technology moves forward at an ever-increasing rate so does our demand on this property which has led to it becoming one if not the top-selling characteristic any polymer composite must possess.

New applications, such as heat sinks in electronic packaging and other devices manufactured with plastics require new composites to dissipate the large amounts of heat generated. These materials often have a low thermal conductivity which can be a significant problem for electronics systems that are turned on or off frequently.

Filling plastics with fillers can make them more thermally conductive than unfilled ones and because there are so many different applications, this is a study area that deserves attention. For example – filled plastic thermal compounds have higher heat transfer capabilities when used in electronics packaging for computer chips which generate large amounts of power or electronic packages where the size has been decreased even though they produce less power. The materials in the circuit board have a high thermal conductivity that is achieved by adding electrically insulating fillers. Alumina, boron nitride, and alumina nitride are all excellent choices for this purpose as they do not change their properties when heated like other substances such as metal or silicon dioxide will.

Boron nitride (BN) is a material with excellent thermal conductivity and resistance to high temperatures. It also has great lightweight properties, so it can be used in many applications that require both heat tolerance as well as being lightweight.

Conductive Types of Boron Nitride

Boron nitride has been used in several industries for its thermal conductivity properties. Conductive ceramics, such as boron nitride, are needed in many applications where high-temperature and harsh environments exist.

Hexagonal boron nitride:

Boron nitride ceramics are traditionally used as parts of high-temperature equipment. Hexagonal BN has excellent thermal and chemical stability, which makes it the perfect candidate for these types of heavy-duty applications. It can be included in ceramic materials to give them self-lubricating properties making them a great option for bearings or steelmaking purposes. Plastics filled with BN have less expansion due to their improved insulation property but also more resistivity when compared against plastics without boron nitride additions, all due mainly because they’re resistant towards extreme temperature changes; this resistance is largely responsible for its dielectric qualities too that make it an ideal material choice within electronics such as semiconductors, microwave-transparent windows and as a structural material for seals.

Cubic boron nitride:

Cubic boron nitride (CBN) is the third hardest material in the world, after diamond and corundum. It has a thermal conductivity of 0.050 W/m·K below 100K but heats up to a molten state as its volume expands past 700K from atmospheric pressure. Thermal conductivity in Cubic boron nitride can be altered by adding thermal insulators, such as air pockets or low-conductive pastes that contain wax particles. Cubic Boron Nitride is an inorganic polymer material that has been extensively researched for its excellent thermal resistance, low-temperature coefficient of thermal expansion, and high heat capacity. The major applications of CBN are in direct contact with things that generate a lot of heat to transfer the energy away from them.

Amorphous boron nitride:

Thermal conductivity in amorphous boron nitride is used to regulate and disperse heat. Common applications include placement behind gas fireplaces to help retain the ambient warmth that flows down from fireplace grates, or as an insulator for window treatments such as shutters or shades on windows. In its unprocessed form, thermal conductivity cannot be manipulated to boost effectiveness; it then must be combined with a cell so that it will respond more easily under varying temperatures. When changing to graphite or amorphous boron nitride laterally (as opposed to end-to-end), there is an increase in thermal conductivity due to reduced resistance at the interface between material layers, thereby increasing the contact area between materials and permitting more heat transfer as well as improving efficiency.

Boron nitride nanosheet:

A conductor of heat, Boron nitride nanosheet is a cutting-edge material that can provide thermal conductivity to any area. Building on the power and versatility of quantum dots, this nano-sheet is impregnated with special properties that allow for ultimate electricity transmission without chemical reactions. It has been successfully applied in over 100 projects across diverse sectors including consumer electronics, military applications, and aerospace engineering. Boron nitride is an extremely efficient conductor of heat. It has been shown to have a thermal conductivity coefficient that rivals copper, one of the most commonly used metals for thermal management in electronics and other applications. The efficiency increases with thickness due to less intra-layer coupling between atoms at thinner layers.

What’s Next

In the world of engineering, many materials can be used to handle heat. One such material is boron nitride (BN). It’s a ceramic compound and has been around for decades with very little research done on it until recently.

Silicon is the most widely-used heat conductor in today’s microelectronics. However, silicon has a major drawback: it does not dissipate heat well and can lead to devise failure if used as the only heat conducting material for high power density devices. Boron nitride (BN) offers an alternative due to its excellent thermal conductivity and low Young’s modulus of elasticity making it ideal for use in multi-layer structures with silicon or other semiconductor materials such as gallium arsenide (GaAs).