The primary source of both boron and borate is the mining of minerals that contain it. Borax, for example, was originally mined from a dry lake in Turkey before being found to be more profitable at other locations such as Alaska where deposits can be located within close access to large mineral processing plants.

The world production amounts to a total of 2,750,000 tons by 1994 with 800 thousand metric tons coming directly from those mines containing 250 million kilograms (kg) or 0.3% B ore which had been processed into commercial products like sodium tetraborate pentahydrate. Most of the world’s commercially recoverable reserves of boron are in the form of the hydrated borate minerals: colemanite (Ca2B4O8.5H2O), pandermite (CaB6O9.7H2O), ulexite (NaCaB5O9.8H2O), and tincal (Na2B4O7.10H2O)

To produce a relatively pure form of boron powder, one can heat the oxide with an aluminum or magnesium flux. This process will cause elemental boron to be created which is about 92% pure. Purer forms of this element are produced by further reducing it from its halides at high temperatures and then growing single crystals via zone melting or Czolchralski method that operates under extremely high pressures for them to grow into large sizes quickly enough without breaking down due to their extreme fragility when exposed too long heated pressure.

Boron and Its contribution to the Economy

The compounds are high production volume chemicals and they’re placed on the European market in amounts that require a chemical safety assessment according to the new European chemicals legislation, Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH).

It is a compound that has found wide application in various industrial processes. It’s an economic element with only carbon surpassing it in a variety of applications among all the elements of the periodic table.

The compounds are used in nuclear technology, as fuel for rockets and fueling the production of heat-resistant materials such as ceramics. The chemical is also used to create high-quality steel that resists heat, polymers which can be made into various items including catalysts or thermochemical storage devices (which store solar energy), glassware, pharmaceuticals, corrosion inhibitors like antifreeze formulations found in motor vehicles, and other cooling systems among others.

Additionally, boron plays a role when it comes to dyestuffs being created with cosmetics like soap detergents flame retardants neutrons absorbers for use by installations handling radioactive material fertilizers disinfecting agents/anti-bacterial, and food preservatives.

A recent study has revealed that waste containing boron makes concrete more cost-effective than ever before, while also being environmentally friendly. The volume of industrial and domestic wastes in many countries has been increasing. Many landfill sites have already been filled up, and finding new sites is difficult. It has been observed that sludge makes up about 46% of industrial waste which means there’s a need to find ways to recover that from sources with high concentrations instead of just dumping the trash into places where it can potentially harm people or our planet.

Periodical of MINERAL COMMODITY SUMMARIES 2020 on Boron

Domestic Production and Use

Two companies in southern California produced borates in 2019, and most of the boron products consumed in the United States were manufactured domestically. U.S. production and consumption data were withheld to avoid disclosing company proprietary data. The leading producer mined borate ores, which contain the minerals kernite, tincal, and ulexite, by open-pit methods and operated associated compound plants. Kernite was used to produce boric acid, tincal was used to produce sodium borate, and ulexite was used as a primary ingredient in the manufacture of a variety of specialty glasses and ceramics.

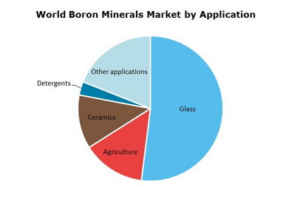

A second company produced borates from brines extracted through solution-mining techniques. The minerals and chemicals were principally consumed in the North Central United States and the Eastern United States. In 2019, the glass and ceramics industries remained the leading domestic users of boron products, accounting for an estimated 80% of total borates consumption. It also was used as a component in abrasives, cleaning products, insecticides, and insulation, and the production of semiconductors.

Events, Trends, and Issues

Elemental is a metalloid with limited commercial applications. Although the term “boron” is commonly referenced, it does not occur in nature in an elemental state. It combines with oxygen and other elements to form boric acid, or inorganic salts called borates. Its compounds, chiefly borates, are commercially important; therefore, products are priced and sold based on their boric oxide (B2O3) content, varying by ore and compound and by the absence or presence of calcium and sodium.

The four borate minerals— colemanite, kernite, tincal, and ulexite—account for 90% of the borate minerals used by industry worldwide. Although borates were used in more than 300 applications, more than three-quarters of world consumption was used in ceramics, detergents, fertilizers, and glass.

China, India, Indonesia, Malaysia, and the Netherlands are the countries that imported the largest quantities of refined borates from the United States in 2019. Because China has low-grade boron reserves and demand for it is anticipated to rise in that country, imports to China from Chile, Russia, Turkey, and the United States were expected to remain steady during the next several years.

Continued investment in new borate refineries and the continued rise in demand was expected to fuel growth in world production for the next few years. Two Australia-based mine developers confirmed that the production of high-quality boron products is possible from their projects in California and Nevada. These companies have the potential to become substantial boron producers when they are fully developed. Both companies expect production to begin in 2021.

(Source: https://pubs.usgs.gov/periodicals/mcs2020/mcs2020.pdf)

Application of Boron in Various Industrial Sectors

GLASS AND TEXTILE FIBERGLASS: The role of Boron in the Glass and textile fiberglass industry is an essential part of the production process. It works with other materials to allow for remarkable expanses of glass, from mirrors to lighting to windows. Without it, there would be considerably more problems when transporting products because containers are lightweight and resistant to atmospheric corrosion or decomposition.

It has also been a major component in Fiberglass as it helps with aircraft strength and enhances its fire resistance capabilities after it’s been baked.

It is an antioxidant and makes the glass easier to shape. It also increases strength and helps reduce thermal expansion. It is not something most people think about when it comes to windows, tableware, clocks, or wine glasses because they don’t see its amazing role in the world! It’s widely used as a strengthening agent for borosilicate glass industry products such as Pyrex ware, Corning ware (when mentioning oven-to-table dishes), and even scientific lab equipment like test tubes.

Agriculture: Boron is a mineral present in soil and is an essential nutrient for plants. It plays a crucial role as it helps with the cell walls, flowering of fruit, cell division, disease resistance, maintaining the water levels inside plant cells. The agricultural sector has made discoveries on how to harness the power of boron by applying them across rice farming practices to help increase yields and improve nutrition production.

Plants need to produce boron internally to give their fruits and vegetables higher levels of fiber, protein, vitamins, minerals, antioxidant health benefits as well as the characteristic taste we know so well like sweet apples or just-picked strawberries on your cereal with vanilla ice cream. It also helps plants grow in low-quality soils where other nutrients are lacking.

Ceramics: The role of boron in the ceramics, enamels, and glazes industry is to stabilize molten glaze compounds. It ions interact with lithium or magnesium oxide (depending on temperature), preventing them from forming a rigid mineral structure. This gives ceramic materials their characteristic flexibility and stops enamel from crazing prematurely when exposed to heat for prolonged periods.

At higher temperatures, it becomes inactive in the glassy state so it can be used as an additive to cut down on molten glass frit shrinkage during blowing processing and produce low-cost thin-walled fibers without any organotin contamination risk.

Boron is a key ingredient in enamels and glazes that give ceramics their high gloss and rich colors. Another essential role of borax is as a binding agent for clays during “greenware.” The greenware becomes fired ceramic when it is placed in an oven at very high temperatures while passing through a salt-water spray misting device called a hydro box.

Detergents: Boron is an element that aids in the cleaning and detergents industry’s ability to clean. It was originally used as an additive for rust protection of metal but now has come become a very significant part of getting rid of dirt, which is cleaned up by sanitation workers with heavy-duty machinery.

Cleansers are good at removing grime from clothes; sometimes they might need to be combined with a disinfectant like Clorox bleach or thorosept biocide before being washed thoroughly. With boron in your cleansers, you can make tough stains go away while doing less damage to your hands and other surfaces. It also helps release unwanted odors so they don’t remain behind on clothes or furniture after washing them. All this without any harsh chemicals that are bad for humans and the environment.

Nuclear energy: In addition to its common roles in animal and plant biology, Boron has a vital role within the NUCLEAR ENERGY industry. It is responsible for regulating nuclear reactions necessary for maintaining stability and providing balance in all atoms during an exothermal reaction. Without this element, nuclear energy would fall out of equilibrium, causing Earth’s atmospheric destruction. In short, it does more than maintain your bone density, it also provides power.

Pharmaceutical use: Boron is a key component of many pharmaceuticals, notably those used in heart medicine. As an essential trace mineral, it plays an important role in the processing and transport of B vitamins: thiamine, riboflavin, pyridoxal-5′-phosphate (vitamin B6), niacinamide (nicotinamide), as well as being cofactor for several enzyme reactions involving vitamin D activation.

Metals and gold: A study in the Journal of Biological Inorganic Chemistry determined that boron is an essential element for the production and stabilization of phospholipids. It acts as a precursor for membrane lipids, leading to stabilization and increased fluidity.

Phosphorylation reactions generated from ribosomes are facilitated by these lipids with borates having a significant effect on protein synthesis. Borates also act as enzyme cofactors in DNA synthesis which leads to transcriptional regulation of many genes; this links borate bioavailability to cell replication rates.

The use of boron is essential in the production of gold, which has made it a widely desired commodity. It plays an integral job holding atoms together with bonds and equalizing buoyancy force among all of its molecules that make up the solid gold form. The atomic number 5 element has ruled over producing gold for centuries because other elements attempt to bond themselves onto the boron’s bonding site or prevent any new molecules from forming by adsorbing common compounds preventing them from being released as liquid surface tension lessens. This material makes an excellent conductor due to its 80 electrons per atom, unlike copper, silver, and palladium who have 34 electrons per atom at their found state.

Oil and gas production: When it comes to oils and gas production, many pieces of the puzzle need to come together cohesively. Material science plays an important role in cementing supply chains, by providing boron delivery systems for these various operations. With Borax, you can reduce energy waste due to corrosion along the supply chain while removing any risk of contamination or leakage. The decreased energy costs also create fewer carbon emissions, which is good for the environment.

How Boron Can Lead To Economic Growth

Boron is an important element that has various applications in different sectors of the world economy. It can be used for agricultural purposes, as well as in construction and manufacturing. These industries are responsible for a significant amount of economic growth worldwide.

It is also used to manufacture fertilizers and pesticides which help farmers increase their crop yield and hence improve the supply-demand balance in the country’s food market. Trade opportunities with other countries can be augmented by exporting these products. This in turn helps in economic growth worldwide which is important to maintain a competitive edge over other nations.