Is Boron the New Carbon?

Today, we’re going to look at whether boron is the new carbon.

Hexagonal boron nitride, a single substance material called white graphene, is highly versatile. It has similar properties to carbon-based graphite in terms of molecular weight and strength and has a transparent appearance.

It’s used in multiple applications, ranging from electrical insulation to cosmetics. Researchers are now saying that given its properties and versatility, the compound is a potential successor to carbon in nanotube science.

Boron nitride

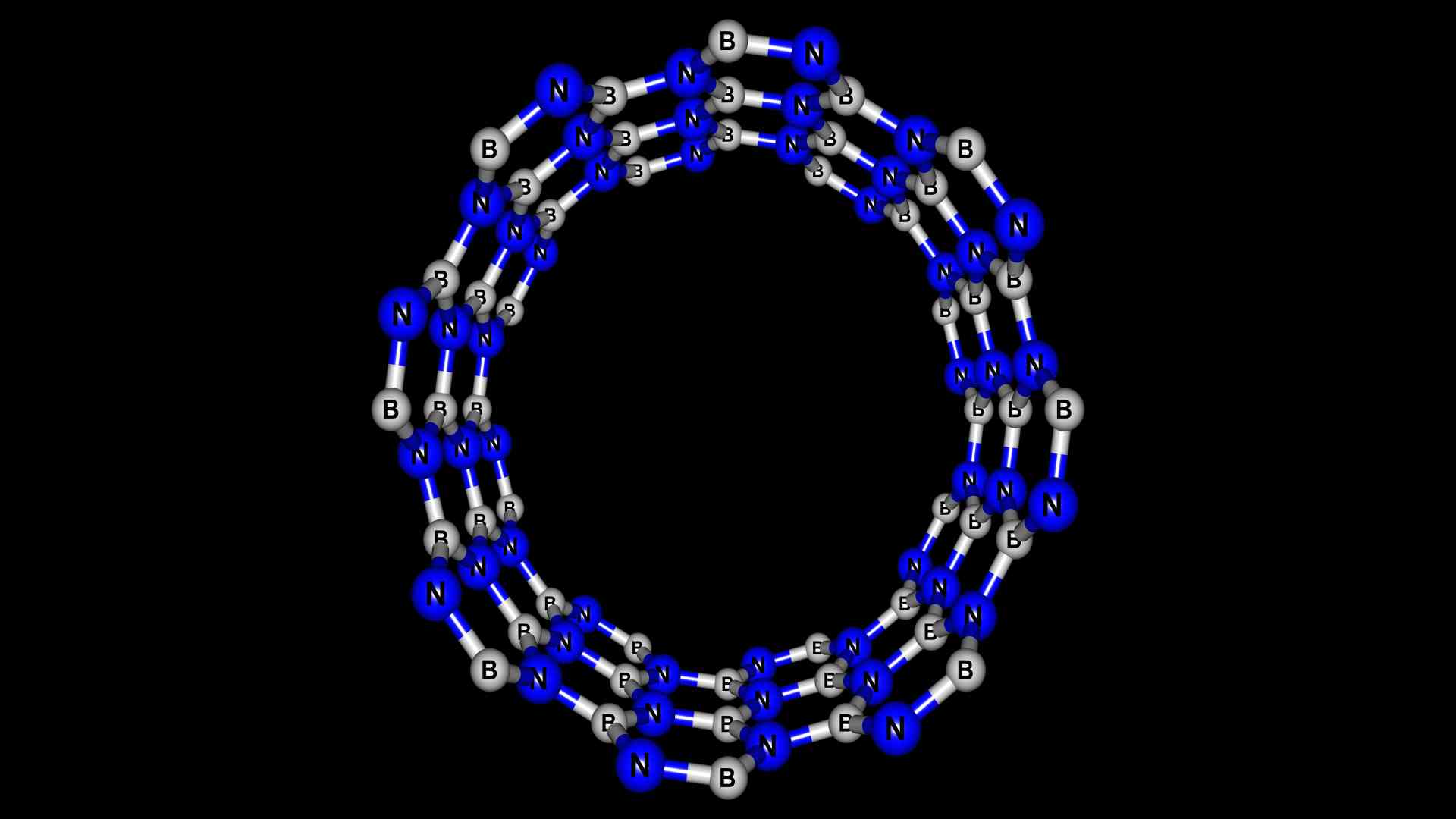

As researchers investigate the potential of two-dimensional materials, hexagonal boron nitride has emerged as a significant player. hBN, like graphene, is made up of a regular pattern of hexagons. But these hexagons are made up of alternating boron and nitrogen atoms. Researchers discovered that HBN sheets have exceptional power, stiffness, and resilience at extreme temperatures.

When these sheets are rolled into nanotubes, their properties are enhanced even further, especially when the nanotubes are closely aligned. These structures are visible to the naked eye and stuffed with tens of trillions of hollow aligned fibers or nanotubes.

Long thin carbon nanotubes were actually first discovered in the early 1990s. Since then, scientists have been perfecting the process of creating these nanotubes in bulk quantities. However, it has proven to be a difficult task.

In a study in 2020, at the University of Tokyo, engineers created tiny structures from hexagonal boron nitride as part of a project looking to incorporate nanofibers into membranes for water filtration and blue energy, a renewable energy principle in which electricity is generated by ionic filtration of seawater into clean water. Their findings, published in the journal AFCs nano, may well pave the way for the mass production of aligned boron nitride nanotubes or A-BNNTs.

Wrong Xiang and colleagues discovered the ability to create high-quality boron nitride nanotubes by developing a forest of a few micrometer-long carbon nanotubes. They used the conventional chemical vapor deposition method and layered it with boron and gaseous nitrogen precursors. These were then solidified onto the carbon nanotubes at high temperatures to produce high-quality, hexagonal boron nanotubes.

MIT Professor of Aeronautics and Astronautics, Brian Wartell, who is taking the research further, says this is all part of a decade-long search for producing carbon nanotubes. Wardle says that aligning the nanotubes makes it easier to utilize boron, nitride nanotube properties in bulk quantities to create physical composites, devices, and membranes. Wardle and Acuan’s study broadens and scales Xiang’s approach, expelling the underpinning carbon nanotubes and leaving the long boron nitride nanotubes alone in place.

The researchers were investigating ways to tweak the pressures and temperatures of the chemical vapor deposition method to eliminate the carbon nanotubes while keeping the boron nitride nanotubes unchanged.

The team eventually discovered a combination of pressures, temperatures, and precursor chemicals. They initially replicated the measures taken by Xiang to generate the boron nitride-coated nanotubes.

They also discovered clear crystallites in the microscopic examination indicating the high quality of the boron nitride nanotubes.

To prove the versatility of their methodology, the researchers developed bigger carbon-based structures such as a carbon fiber weave, a mat of fuzzy carbon nanotubes, and sheets of randomly distributed carbon nanotubes.

Before burning the underpinning carbon, the team layered carbon-based specimens with boron and nitrogen precursor chemicals. In every demonstration, they were given a boron nitride scale model of the actual black carbon scaffold. They also demolished BNNT forests, resulting in horizontally aligned fiber films, a favored configuration for integrating into composites.

Wardle and his further worked on bulk scale clusters and fibers to strengthen composite materials for space and hypersonic applications, being heat-resistant and more powerful, and for use in window panes and optically transparent devices.

A measure of the interest that these studies have gained is shown by the list of industry partners who have contributed to the research with funding and or partner research resources through MITI’s NECST (or nano engineered composite aerospace structures) Consortium. These partners include ANSYS Airbus, Boeing, Lockheed Martin, Embraer, Saab AB, and Teijin Carbon America.

And that’s all from Borates Today. For more information on applications and benefits related to boron and borates, please consult our website borates.today.

Thanks for listening!