Novel Applications in BNNTs

Today, we will look at novel applications using boron nitride nanotubes.

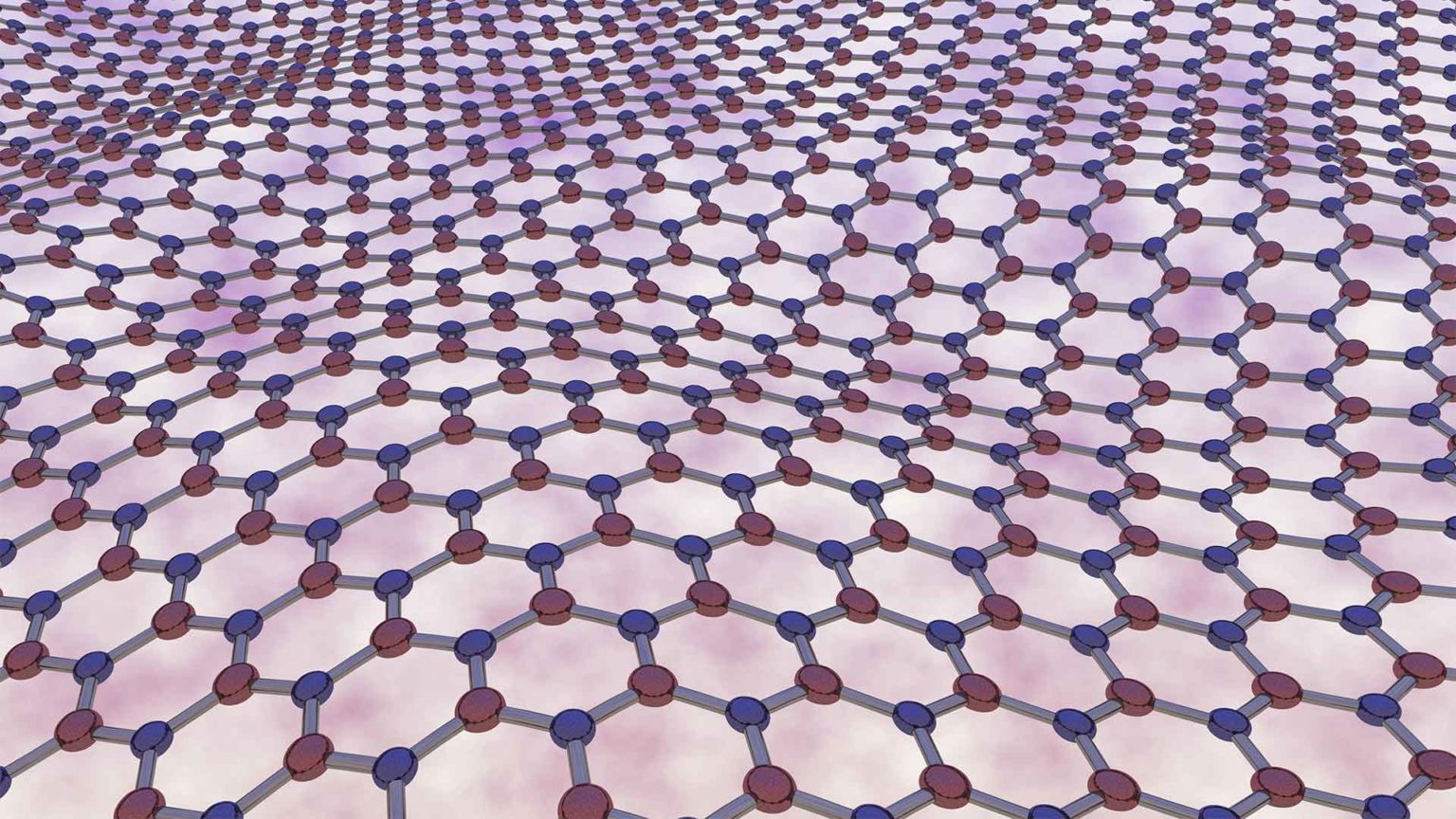

Boron nitride nanotubes, or BNNTs, are mechanically and structurally identical to carbon nanotubes. BNNTs, however, have unique properties that are electrically insulating as well as transparent because of the polarized boron nitride bond.

Boron Nitride Nanotubes

These properties have kept BNNTs from being used for energy harvesting or electronic devices for over 25 years. The invention of the National Aeronautics and Space Administration Langley research center in 2014 made BNNTs commercially available for the first time and has allowed for a broad range of applications.

Researchers have since begun to show a variety of new applications for BNNTs over the last few years. These novel uses are based on properties that are not available in CNTs or carbon nanotubes. Additionally, these applications also include osmotic energy harvesting using the charged outer surfaces of BNNTs.

Single electron room temperature transistors use insulating bin empties as tunneling channels, high brightness fluorophores that can shine a thousand times brighter. It works better than regular dyes or transistors from Tullerian atomic chains filled with BNNTs and transistors based on tellurium atomic chains.

Commercially BNNTs have the advantage of being nanoscale and having an aspect ratio similar to CNTS. BNNTs have better wetting, mechanical strength, and thermal resistance properties than CMTS. These properties are beneficial for many applications, including electronic drug delivery. biomedical, aerospace, energy, environmental, and other medical fields.

Composites made of BNNTs can enhance mechanical reinforcement and structural composites, thermal conductivity, high-temperature material processing, high-temperature applications, piezo-electronic electric sensing, and energy harvesting. This wide range of applications for BNNT composites is essential for membrane science.

There are currently a variety of studies that focus on ceramic or polymer membranes and the benefits of BNNTs.

Also, nanotubes are gaining considerable attention as membrane materials because of the high surface-to-volume ratio. A number of studies have been done on membranes using CNTs, Silicon nanotubes, and halloysite nanotubes. CNT composites have demonstrated high performance in membrane applications, including permeability, selectivity, mechanical strength, and thermal properties.

BNNTs have similar properties to CNTs then, but they have better properties in terms of wettability water, permeation, thermal conductivity, resistance and strength, and mechanical strength when used to make composite materials for membranes.

In terms of applications, the new composite could also revolutionize WAM or wire additive manufacturing by enjoying global commercial industry implications for applications in 3d metal printing. These new projects are a step towards widespread commercial adoption. BNNTs will revolutionize the advanced materials market with improved global production capacity and lower per-unit production costs.

One company, AML3D, is eager to enhance this emerging technology using 3D metal printing, to further the competitive advantage of its own patented. WAM technology.

AML3D Limited has patented a wire additive manufacturing process in which metal 3d prints out large-scale commercial parts for aerospace, defense, manufacturing, mining, oil, gas, and maritime.

BNNT is the most robust and advanced fiber globally. It can significantly enhance the properties of WAM-deposited alloys. Adding BNNTs and aluminum to other metals can also result in stronger, lighter, and more radiation-resistant alloys. Listed on the ASX, AML3D Limited is examining two new methods for incorporating BNNTs in aluminum in the context of wire additive manufacturing with a view toward rapid commercialization.

On November 2nd, 2021, the company announced that it would produce a specialized high-strength alloy part for a yet-to-be US aerospace company. The company will supply a high-strength and corrosion-resistant alloy shape using the above boron-based proprietary WAM technology. This will permit AML3D to play a strategic role in the rapidly growing space exploration sector and open the door to further collaboration with other global aerospace organizations.

Deakin University Senior Commercial Manager, who is working with AML3D commented Deakin University is generally excited to be collaborating with AML3D to explore the feasibility of incorporating BNNTs with aluminum. Utilizing the patented WAM technology, this research presents a unique opportunity to develop advanced materials with superior performance and a whole new range of applications for AML3D and its customers.

As just one example of what is going on in innovative technologies using BNNTs, the future is exciting for the development of more commercial applications.

And that’s all from Borates Today. For more information on applications and research related to boron and borates. Please check out our website. Thanks for listening.