Boron Zinc Borates for Superior Fire Protection

Many different uses can be made of fire-retardant chemical chemicals. Fire retardants are used to protect people and property against fires caused by electrical equipment such as transformers, circuit breakers, and power lines.

Fire Retardant Chemicals

Boric acid is the most popular type of fire retardant chemical. Boric acid is a common fire retardant chemical that has been in use since the early 1900s when it was introduced into the United States to add to wire insulation.

Boric acid’s effectiveness as a fire-retardant started to decline after World War II. The U.S. Department of Defense produced a new type of fire retardant that was more effective at controlling fires than boric acid in the 1960s. These fire retardants are based on ammonium-polyphosphate salts, which are more resistant to water than boric acids. These fire retardants came with several drawbacks. They could not be directly applied to the insulation material.

To address the problems caused by the older fire retardants, the U.S. military invented a new type of fire retardant called Zinc Borate Esters. ZBE fire retardants address all the issues previously mentioned. They can be applied directly to insulating materials, don’t require special handling procedures, and work well with nearly any insulation material.

Zinc Borate components within the solution

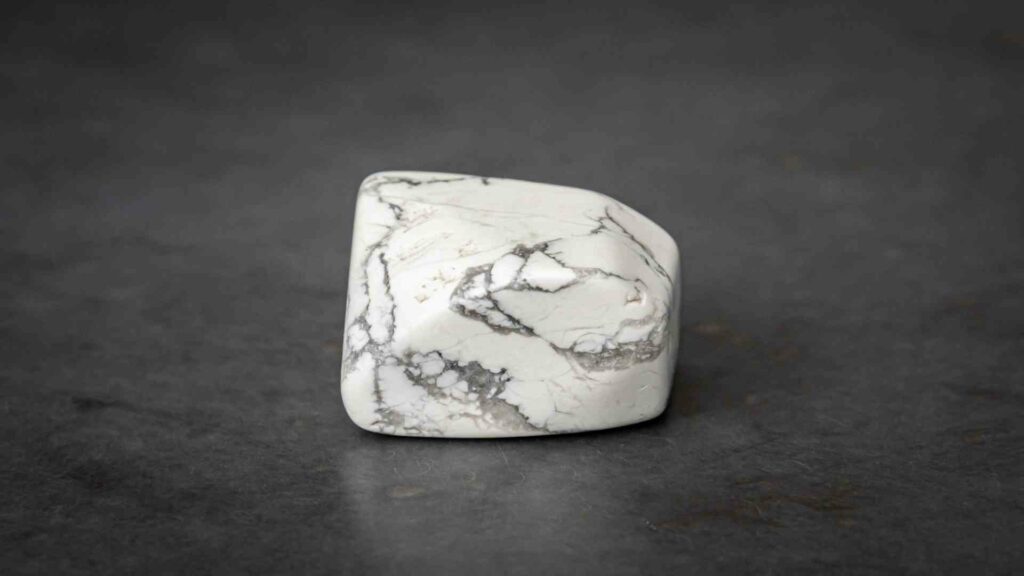

Zinc borate esters are composed of two main components. One is a metal oxide (or hydroxide), zinc, aluminum or magnesium, calcium or strontium. The other component is usually tin or nickel. The complex salt contains a metal oxide or hydroxide, usually about 5% to 50%. It is best to have about 10% to 30% glycol dimethyl phosphate and other compounds.

The physical status of ZBE

Zinc borate esters, which are highly stable compounds, resist degradation over time. They are suitable for storage and transportation over long periods due to their stability. They also do not corrode insulation materials. They also have excellent fire-fighting properties. The volatile gases they produce are converted to oxygen by heat. This helps extinguish fires.

ZBE fire-retardants over boric acid have three significant advantages:

- ZBE fire suppressants are less expensive than boric acids; ZBE flame retardants provide better protection against fires, while ZBE fire resistants are also more eco-friendly.

- ZBE fire retardants tend to be less expensive than boric acids due to their lower cost. Boric acid costs approximately $1.50 per gallon, while ZBE fire retardants are only $0.25 per gallon.

- ZBE fire retardants are also superior in protecting against fires. ZBE fire retardants work better than boric acid in protecting people and properties from fires.

Market adaption of ZBE Fire retardants

A study done by the National Institute of Standards and Technology revealed that ZBE fire-retardants are twice as effective in preventing fires as boric acid.

ZBE fire retardants can be used in an environmentally-friendly manner. Federal law has Boric acid classified as hazardous. ZBE fire retardants, however, are still considered “green” because they can be biodegradable.

Several companies can manufacture ZBE fire retardants. Arkema Inc., Chemours Company, Chemetall GmbH, DuPont, Ecolab Inc., Evonik Industries AG, Huntsman International LLC, Honeywell International Inc., Lubrizol Corp., Mitsubishi Chemical Holdings America Inc., Nalco Holding Co., Northrop Grumman Innovation Systems Inc., Owens-Illinois, Inc., PPG Industries Inc., Solvay SA, Sumitomo Chemical Co., UOP LLC, Wacker Chemie AG, etc.

Analysis of Fire Retardants Containing Zinc Bromide

Zinc bromide has long been used as a fire retardant since the 1940s. It was initially introduced to polyurethane-based foams as an addition. It is still a very popular additive to other types of insulation materials.

If zinc bromide is heated, it releases hydrogen bromide, which can help extinguish fires.

Zinc bromide, however, is highly toxic and corrosive. Inhaling it can cause serious health problems. It can cause severe stomach pains, vomiting, diarrhea, cramps, or even death if swallowed. Furthermore, zinc bromide is flammable. Exposure to high temperatures will cause it to ignite. It can burn through any material that comes into contact with the air.

Zinc bromide can’t be shipped by air freight because of its toxicity and corrosiveness. Zinc bromide must be shipped on trains or trucks. Transport costs are a significant expense when making this type of fire retardant.

The downside to zinc bromide is its difficulty in producing. For zinc bromide production, most manufacturers use a process called “halogenation.” This process consumes a lot of energy. There are also environmental concerns when producing zinc bromide by halogenation. Halogenated chemicals have been identified as carcinogens, mutagens and are harmful to the environment. They are also dangerous for the environment.

For years, the industry has searched for alternatives to zinc bromide. There is an alternative, magnesium bromide. It does not have these issues. But magnesium bromide is far less effective than Zinc bromide.

Recent years have seen some companies develop new fire retardants with zinc bromide. ZBE fire retardants are zinc bromide, other borax, potassium carbonate, and ammonium phosphate. These fire retardants are made from zinc bromide combined with ammonium-phosphate and potassium carbonate. The powder is then mixed into various insulation materials.

Aluminum hydroxide is an aluminum-based additive that companies use to reduce the amount of zinc bromide needed. Aluminum hydroxide is a water-soluble additive that absorbs moisture from the air around it, which reduces the fire’s speed.

Others have also combined zinc bromide with other flame retardants. Here are some examples of such combinations:

1) A combination of zinc bromide (Ca2B4O7*10H2O) and calcium tetraborate. Alcan/Aluminum Corporation of America sells this combination under the brand name “Tetra-Brite.”

2) A mixture of zinc bromide, sodium borate. Sparco Incorporated sells this combination under “Spitfire.”

3) A mixture of zinc bromide, ammonium phosphate. Kaneka Corporation markets the combination as “Kanex.”

4) A mixture consisting of zinc bromide & ammonium sulfamate. Akzo Nobel markets the combination as “Firemaster.”

5) A mixture consisting of zinc bromide, ammonium triphosphate, and other ingredients. Vitro Industries Limited is marketing this combination as “Vitality.”

6) A mix of zinc bromide, ammonium phosphate. Flexicoil Corporation markets the combination as Flexi-Shield.

These combinations all work very well to slow down fires. These combinations may not work with all types of insulation. Because fiberglass is made differently, it might not work with them. Fiberglass insulation is composed of long fibers which are joined by resin. Fiberglass melts when it is heated and then flows outwards. It releases heat when the resin melts. If the resin is sufficiently hot, it can start to smoke. The fiberglass may look darker because of the layer of smoke that can be formed on top. It creates a fire that looks just like a chimney.

Zinc bromide will not work with many fiberglass insulation resins. When fiberglass insulation is mixed together with zinc bromide, it tends to separate the resin. This makes the insulation more resistant to fire and less effective.

Additives to the resin can solve this problem. It should be noted, however, that adding additives increases the cost of fiberglass. A different type of insulation is another option. One could opt for Rockwool or mineral wool to replace fiberglass. Mineral wool, which is similar to fiberglass, is made out of glass instead of plastic. Rockwool is a natural product derived from volcanic rocks. Both Rockwool and mineral wool are more expensive than fiberglass.

Compound fire retardants

It is possible to combine zinc bromide, with other compounds, for a more practical approach. Boric acid is a good example. Boric acid is a chemical composition that contains four hydrogen atoms bound to oxygen atoms. It has two primary uses. The first is to fertilize. One other benefit is to be a component of fire retardants.

Boric acid can be used in combination with other ingredients. Examples include calcium chloride, magnesium hydroxide, ammonium sulfate, potassium nitrate, sodium silicate, and urea-formaldehyde.

Because each ingredient has different properties, they can be used together. Calcium chloride is an excellent example of how calcium chloride can help prevent fires. It makes the wood surface less flammable. Magnesium hydroxide makes paper’s surface less volatile to heat. Ammonium Sulfate is a preventive agent against fires. It absorbs moisture and stops the growth of new fires. Potassium Nitrate prevents fires from spreading. Sodium silicate can help reduce the rate of fire. Urea-formaldehyde prevents fires from burning too hot.

If the ingredients are properly combined, they will create a mixture that can stop fires but not cause any harm to people or animals.

Other fire retardants

Rockwool

Michael J. has written the book “How to Make a Better Fire,” which will provide more information on fire retardants. Fox. This book contains all you need to know about fire-retardants. It covers everything you need to know about fire retardants, including where to find them and how to use them in your home.

Rockwool(r), which is a famous fire retardant, is the most common. Rockwool (r) is made from tiny glass fibers which act as small rocks. Rockwool(r), which melts when exposed to high temperatures, releases its liquid form in the air. This happens because the liquid cools down and then turns back into solid particles. These particles settle on the ground and form a layer called rock wool.

This is repeated until the entire area covered with the fire retardant is covered in rock wool. The fire doesn’t burn through the rock wool layer. Instead, the fire smolders under the layer of Rockwool. This means that the fire doesn’t reach the building’s underside.

You can also spray the fire retardant directly onto the flames. Spraying can be either done manually or automatically. You should use gloves, goggles, or boots if spreading yourself. Make sure you have adequate ventilation so that you can inhale any fire retardants.

Chemicals

There are also automatic sprinkler systems available that include chemicals to extinguish a fire. These sprinklers are often installed in areas where they are most likely to catch on fire. Sprinklers are usually placed in regions that have high electrical conductivity and where people spend a lot.

Sprinklers may seem costly, but many homes already have them. Some homes have sprinklers built right into their walls.

Sprinklers are great for keeping fires from certain parts of your house. Sprinklers may not be enough to protect your home. You may need more than a sprinkler to put out a flame.

Fire extinguishers

A fire extinguisher is an apparatus that contains a chemical that is used to extinguish a fire. A substance called Halon 1301 is used to extinguish fires. Halon 1301 is a substance that fills in the space between oxygen molecules. The result is a reduction in the amount of oxygen that can be used to light the fire. Halon 1301 has been rated as one of the safest fire-extinguishing agents. But there are different types of fire extinguishers. Some extinguishers use CO2 gas while others use water.