Boron wearable memory devices

Boron wearable memory devices: Developing boron-based nanomaterials for flexible memory devices for wearables is being explored by researchers in Korea. The devices can potentially be used to store, process, and communicate data on the move.

Boron Smart Wearable Devices

Wearable Device Research Underway

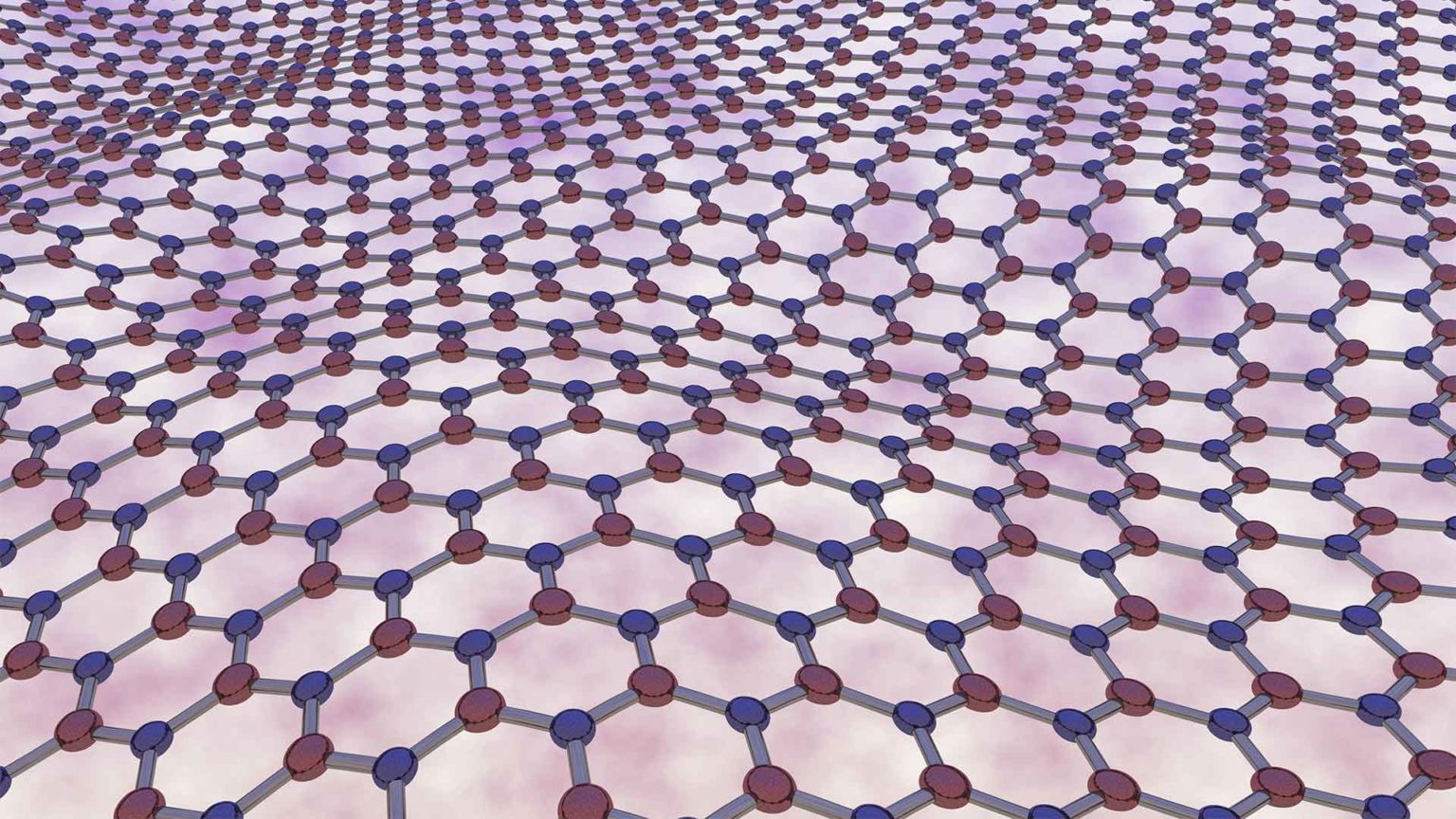

A research team led by Professor Dong-Ick Son from the Korea Institute of Science and Technology has developed a transparent ultra-thin memory device based on a low-dimensional, heterogeneous nanostructure. The new material consists of monolayer, zero-dimensional (0D) quantum dots sandwiched between two-dimensional hexagonal boron nitride (h-BN) nanomaterials. Researchers are now working on integrating the resulting materials into a high-density memory cell.

A thin and flexible memory device made from boron is at the heart of this next-generation wearable technology market research. Flexible memory is essential to processing and storing data. The memory device has a low-set voltage and a high switching current ratio. The transparency of the material also increases its storage capacity.

The researchers have used two-dimensional boron-based nanomaterials to develop a transparent ultra-thin memory device. While conventional 2D nanomaterials have poor carrier trapping properties, boron and cadmium nitride composites have excellent trapping characteristics.

By introducing 0D quantum dots with exceptional quantum limiting properties into the active layer of a 2D nanomaterial, the team has developed a device that could become a memory candidate of the future.

The device is transparent and flexible, comprised of 0D quantum dots stacked vertically between 2D hexagonal h-BN nanomaterials. The developed device maintains more than 80% transparency and memory function even when bent.

Exciting Possibilities

Professor Dong-Ick Son states, “As an alternative to graphene, we have developed a method for controlling quantum dots on insulating hexagonal BN that has laid the foundation for ultra-thin nanocomposite structure research, revealing new concepts of fabrication and operation for next-generation memory devices.”

“We plan to expand the range of applications of stack control technology to include a variety of low-dimensional heterogeneous nanomaterials.”

Flexible Properties

With a 2D nanomaterial materialized into an ultra-thin memory device of several nanometers (nm), its density can be dramatically increased, developing a flexible resistance-variable memory that utilizes the 2D nanomaterial.

The Role of Boron and Wearable Memory

The unique physical properties of Boron Nitride Nanotubes (BNNTs) make them one of the most promising candidates for commercialising this research. BNNTs are already used in various fields, including electronics, energy, biotechnology, and medicine. Because they are so good at conducting electricity, they’ve been touted as a new high-performance electrode material for supercapacitors.

Boron Nitride Nanotubes

A BNNT based on amorphous boron has a crystalline structure, exhibiting resistance and a resistance window. The hBN film is also transparent, with a high-density boron film. As a result, it is transparent. The BNNTs are highly effective in charge storage NVMs and can be used in future devices to increase the storage density.

The BNNT spheres were grown directly on a-Al₂O₃-a-um-range particles. The BNNTs displayed a resistance window and a low opening voltage, and amorphous boron was also seen to be highly conductive. The BNNTs also show controlled boron release.

Despite the fact that a transparent ultra-thin memory device may be difficult to fabricate, the device is already on the way to becoming a reality. The two-dimensional layer is a layered structure that enables the formation of a conductive filament. The QDs in an hBN are made of highly stable metal. It can withstand high temperatures and electrical fields and retains information for a long time.

Other Wearable Device Research

Biocomposite materials are another excellent candidate for transparent ultra-thin memory devices. These biocomposites have excellent flexibility, stability, and eco-friendliness. They are also highly flexible, allowing for a high degree of translucency. Unlike their bulk counterparts, they retain their memory functions even after being bent. The biocomposite enables a high-density, transparent ultra-thin memory.

The use of nanoscale Ag-modified cellulose nanofibers as a transparent ultra-thin memory device was demonstrated by researchers. The researchers also found that nanofibers could be used to improve the memory properties of biodegradable materials. The resulting materials also showed high flexibility.

The fabricated nanomaterials were covered with silk, which stabilized the structure. Then, the silk and CDs-coated multi-wall carbon nanotubes were embedded into the fabricated thin films. The fabricated devices showed a remarkable Vth shift after a UV programming operation. Holes were transferred from the CDs-silk charge-trapping layer to the pentacene layer during the process. The resulting material was able to accumulate high conductivity.

The development of high-density nanostructures has been hampered by the lack of adequate information storage in such devices. As a result, the development of ultra-thin devices has been hampered by several challenges, including a lack of high-density chips. While many of these new technologies are in the early stages of development, their use is a major source of innovation.

Structure of Boron Nitrogen Nanotubes

BNNTs are formed from metal catalysts at high temperatures and pressures. Although BNNTs can be synthesized, there are many challenges associated with the process, including difficult control of the tube’s shape and size and the need for costly equipment. It has thus long been desired to develop methods for synthesizing BNNTs at room temperature.

Recent research has attempted to make BNNTs at room temperature using a technique called ‘vapor liquid solid’ (VLS). BNNTs are produced by this method by using a catalyst solution containing transition metals such as Fe, Co, Ni, Cu, etc. When the catalyst is heated, the solvent vaporizes, resulting in the precipitation of the transition metals onto the substrate surface. BNNTs are then nucleated on the catalyst particles. Presently, single-walled BNNTs are produced using VLS. BNNT structures with multiple walls, however, are difficult to obtain by this method.