5 Ways Boron Can Be An Approachable Extrication Agent

Although the use of boron for extrication is not a new innovation, it has been recently gaining traction in the emergency services industry. It is used to create an intense alkaline environment that will burn through various materials including fabric and metal – making it a great tool for first responders who are often faced with difficult situations involving clothing or other material.

Let’s first understand what exactly extrication means. Extrication is the process of removing an object from a confined or restricted space. Extrication can be accomplished by using self-contained breathing apparatus, protective clothing and equipment designed for hazardous materials. The word “extricate” comes from the Latin extirpate meaning “to cut out”. It can involve tools such as hydraulic jacks, prying bars and shovels. Vehicle extrication is the process of removing a vehicle from around a person who has been involved in a motor vehicle collision when conventional means of exit are impossible or inadvisable.

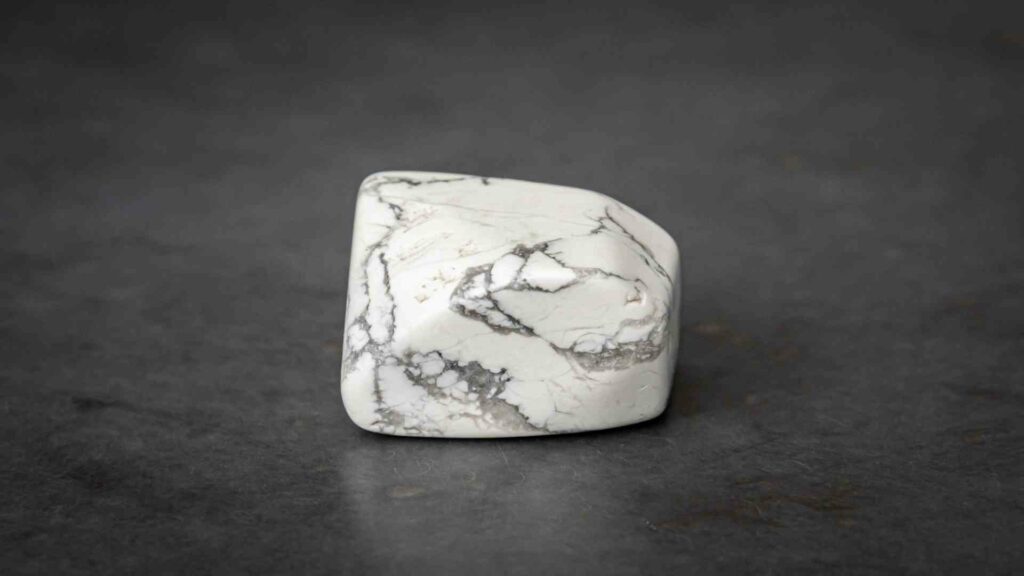

Boron Steel

The use of boron steel in extrication is an important factor to consider because it has a tensile strength that’s close to titanium, which makes it perfect for emergencies where you need something durable and strong enough to cut through metal or other materials to extract people from dangerous scenarios.

Boron steels find use in the car industry, typically as strengthening elements such as around the door frames, and in reclining seats. As of the mid-2000s it was in common use by European car manufacturers. The introduction of boron steel elements introduced issues for accident scene rescuers as its high strength and hardness resisted many conventional cutting tools (hydraulic shears) in use at that time.

Boron steel is used in the shackles of some padlocks for cut resistance Boron steel padlocks of sufficient shackle thickness (15mm or more) are highly hacksaw, bolt cutter, and hammer-resistant, although they can be defeated with an angle grinder.

Extraction with traditional tools can take hours on end-boring work that often causes more harm than good by causing panic among victims trapped within their vehicle; not only does this process make rescuers feel like they’re getting nowhere fast but it also means less time spent at each extraction site because there are so many others waiting around as well.

- The use of boron as an extrication agent is not new, but it has been gaining traction in recent years because of its effectiveness and low toxicity.

- It can be used to remove people from vehicles that have caught on fire or are submerged in water, for example; the chemical reacts with glass and metal surfaces to create a protective layer that prevents further corrosion or deterioration.

- It is also useful when removing people who have become trapped under heavy objects such as collapsed buildings or fallen trees – by spraying boron onto the object, rescuers can then move it without causing injury to those underneath it.

- It’s ability to react quickly means that there is less risk of secondary injuries caused by heat or pressure waves than other chemicals would cause during an extrication operation; this makes it ideal for emergencies where time is limited and lives are at stake!

- In addition, unlike some other chemicals used in these situations (such as chlorine), borax does not produce toxic gases when mixed with water so there’s no need for masks while using this substance!

Boron’s Unique Properties

Boron is a unique metal, and its properties make it an excellent choice of extrication agent. As you can see from this blog post, it has many uses in the construction industry that may not be immediately apparent to some people. For example, as long as there are no other complications during an accident such as prolonged exposure or ingestion by bystanders, it will help with emergency personnel during extraction efforts on injured parties. If your company deals heavily in vehicular construction or removal (e.g., tow truck services) then we recommend using boron steel for all equipment involved due to its strength and resistance against corrosion over time.