Boron in Eyewear

Boron in eyewear has been used as an essential ingredient for manufacturers of optical materials since 1887 given its water-soluble presence, with benefits including durability, resistance to scratching, and suitability for light transmission. Borate minerals such as potassium borate, sodium tetraborate, and boric acid are widely used in manufacturing optical materials.

Boron in Eyewear

Boron Compounds Used in Eyewear

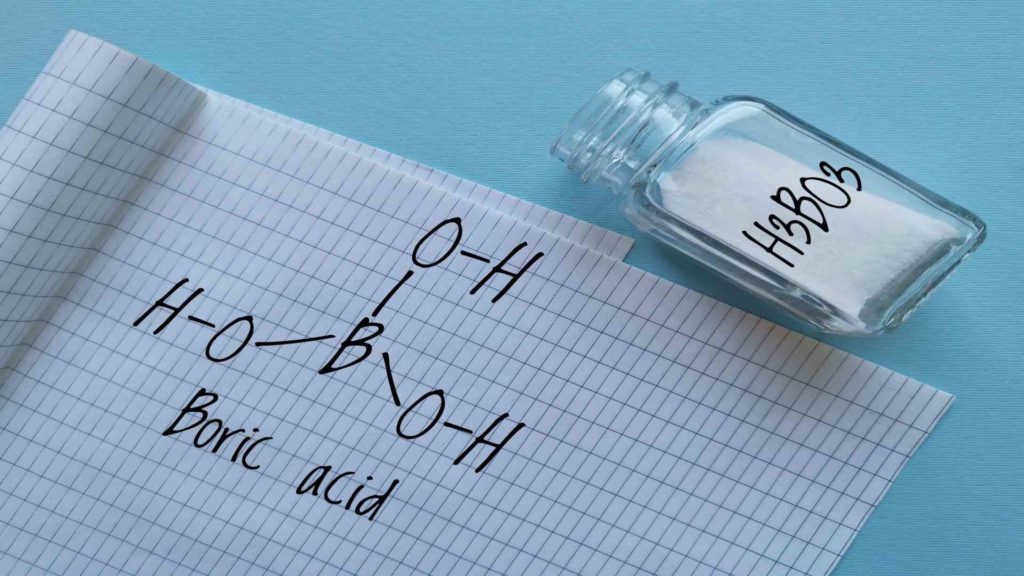

Borate minerals used in optical materials are a group of bivalent anions that include boric acid, sodium tetraborate, and potash. Primarily, boric oxide is used to make optical glasses. It allows for the creation of glasses with particular optical properties in light dispersion and refractive index. To prevent any contamination, some optical glasses are made in continuous tank furnaces that have been completely lined with platinum. Automatic press equipment is used to produce lens blanks from the glass melt. The average boric oxide content of optical glass can vary from zero to 40%.

Borate minerals are usually in water-soluble form. These minerals, such as potassium borate, sodium tetraborate, and boric acid, help increase the refractive index of glass or plastic by up to 1%. This is possible with a solution applicable on the surface during the manufacturing process. The use of borates has many benefits, including lower production costs, increased light transmission, and improved durability against scratches.

Borate minerals have optical materials such as glass for laboratory use and plastics. Boron oxides are also in optical elements like lenses, prisms, windows, mirrors, or other devices. Particularly the ones that can reflect light or other electromagnetic waves.

How Boron Helps Eyewear Performance

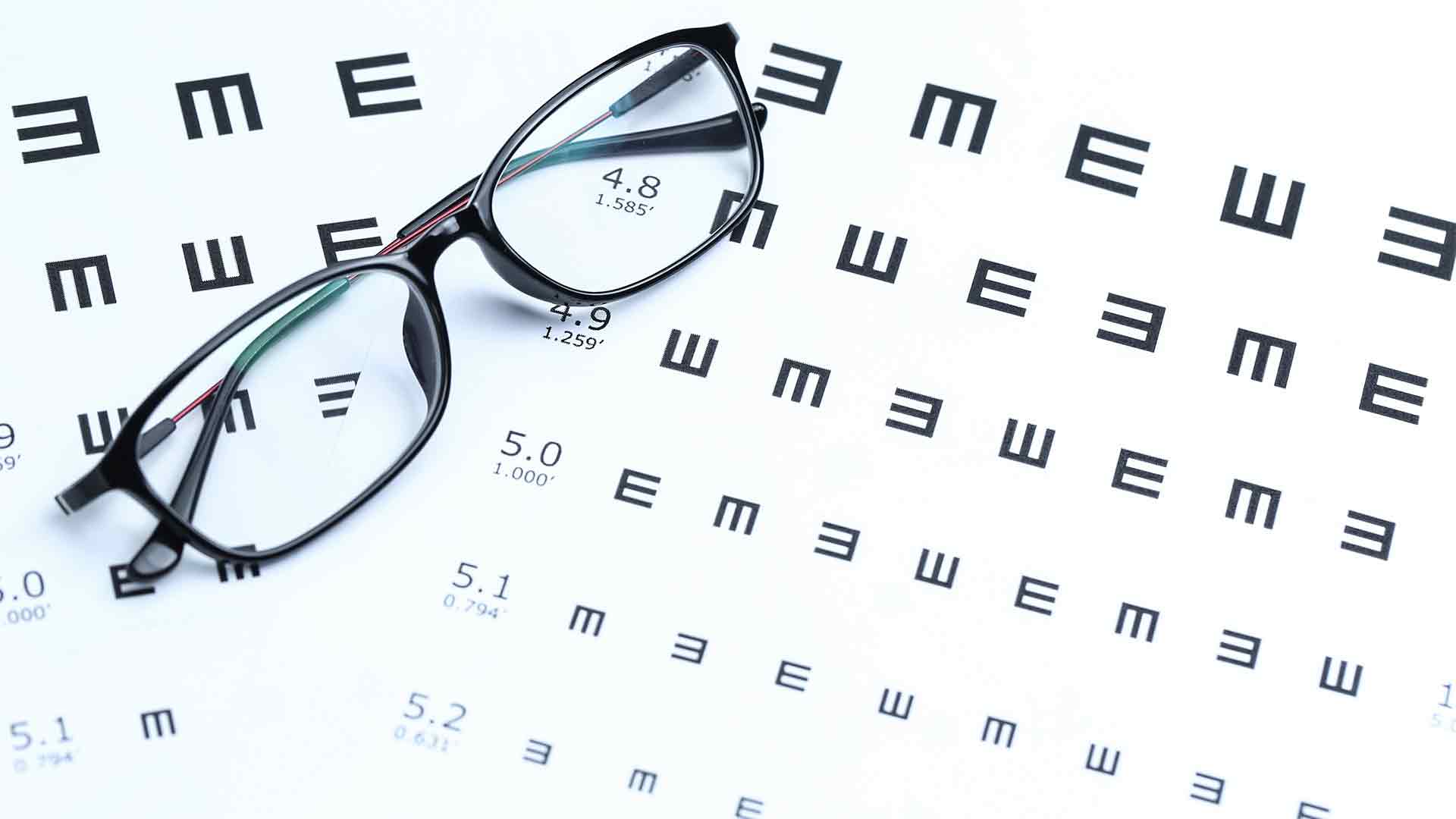

The Refractive Index

Borate minerals withstand higher operating temperatures and deliver a lower refractive index than other types of glasses.Borate minerals withstand higher operating temperatures and deliver a lower refractive index than other types of glasses.The refractive index is an important property when considering lenses. It is vital because it determines how much light will pass through the lens according to Snell’s Law: n=sinθ/sineθ+1. Increasing this value will allow more light through the lens, improving vision.

These borate minerals are crucial in producing certain glasses because they lower the refractive index at which light becomes visible within the material by about 0.001%. This means that light will not reflect off surfaces on the glass. Boron oxide, calcium borate, and magnesium borates are all used to produce glasses to help them maintain their transparency over time.

Anti-reflective Properties

The use of borates also produces glasses with an anti-reflection function without resorting to expensive metals like silver or gold for coating.

Scratch-proof and High Durability

Borate glasses are over 100 times more effective than regular glass. Especially when protecting against scratching, it makes them the primary choice for lenses in eyeglasses and sunglasses. Due to this, they are highly durable.

Resarch into New Oprical Mateiral with Boron

Research continues to find new boron compounds which will provide more efficient and effective optical materials. One such study, Borates: A Rich Source for Optical Materials by Miriding Mutailipu, Kenneth R. Poeppelmeier, and Shilie Pan, appears in 2021 in the Chemicals Review. The study presents a clear chemical perspective of borates to “facilitate the discovery of new borate-based optical materials”.

The search for “novel borates with superior performance is greater than ever before. Through the sustained efforts of chemists and material scientists, more than 3900 boron-containing compounds, including borate minerals and synthetic borates, have been documented in the scientific literature”.

The review provides a survey of all the reported anhydrous borates and an analysis of their structural chemistry. State-of-the-art progress related to technological advances in borate-based nonlinear optical, birefringent, and self-frequency-doubling materials is surveyed.

A Short History of Eyewear

In the 13th century, Italian monks were the ones who first created semi-shaped ground lenses. These lenses worked in the same way as magnifying glasses. The monks used beryl, a type of quartz used to make the lenses.

Edward Scarlett, a British optician, invented the modern eyeglasses frames in 1727 that could be worn over the nose and ears. These eyeglasses were made with glass lenses and heavy copper, lead, or wood frames. Later frames were made from natural materials like leather, bone, and horn. Lighter frames made of steel were developed thereafter.

Boron was first introduced into glass production back in 1887 by Otto Schott. Schott was looking for something to strengthen his weaker glass products without introducing coloration effects from lead compounds used at the time.

Plastic lenses were introduced in the 1980s as a durable option to glass lenses. The eyeglasses we wear today are thus a culmination of centuries of technological and scientific advancement.

Key Takeaways

Borates are an indispensable material for the optical industry. They have been in glass production since 1890. And they will continue to be a staple for glass manufacture, even as other materials such as silica take on more of the burden.

There are, however, some drawbacks, such as being brittle and having a relatively low melting point. But the benefits overcome any disadvantages: High refractive index and low absorption coefficient; high durability, and cost-effective.