Boron Flat Panel Display Glass

Boron Flat Panel Display Glass is an important mineral used in LCD and plasma television panels. It is commonly used in high-tech glass for LCD and plasma TV screens. Its use in these products significantly increased around 2000 as consumer preference shifted away from CRT TVs to flat-panel screens. Substitutes for boron are, however, beginning to appear given its presence in glass, which some consider an environmental hazard.

Boron Flat Panel Displays

Boron Compounds used in FPDG

The term flat panel display (FPD) may be used to refer to any number of “flat” display technologies, such as liquid crystal displays (LCD), plasma displays, and field emission displays (FED).

FPDs use borosilicate glass primarily for TFT displays. Since flat panel displays (FPDs) have replaced cathode ray tubes (CRTs) in markets such as televisions (TVs) and computer monitors, thin-film transistor (TFT) glass has historically been an important market for borates. The most common type of FPD is the LCD, which utilizes TFTs glass in manufacturing the devices.

Using boron in flat panel display glass continues to be widespread. Boron exhibits advantages in heat resistance, processing range, and devitrification stability in Flat Panel Display Glass. Other benefits of boron in flat panel displays include improved brightness and colour rendering, and boron-infused glass can even improve the display’s contrast

Constructing TFTs

Displays with TFTs are constructed using two sheets of alkaline-free borosilicate or boroaluminosilicate glass between which is a filling including TFTs (which control the electronic current to the pixels), transparent conductors, and colour filters.

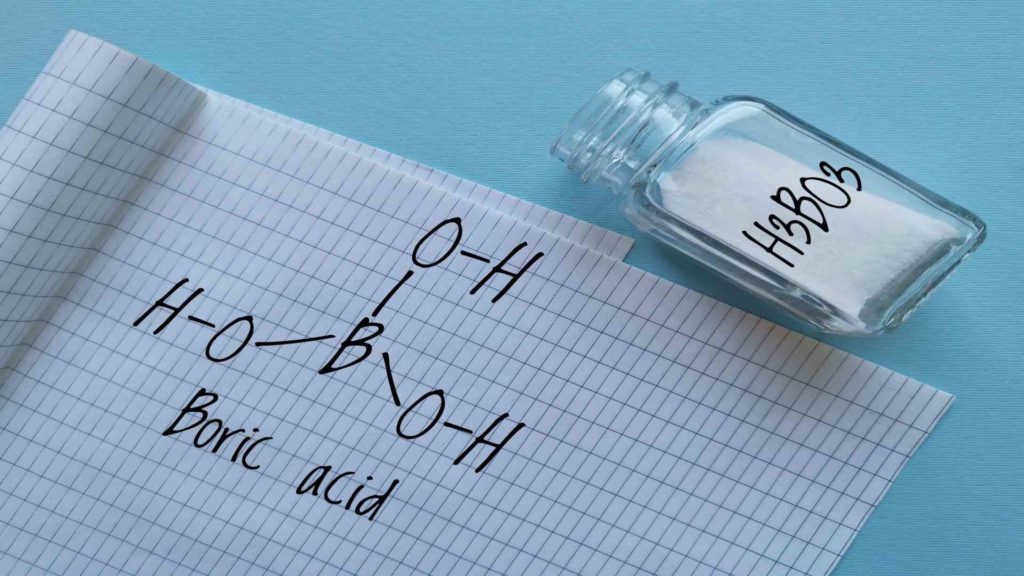

The glass used in these substrates mustn’t contain alkaline elements, such as sodium, since these may interact with the TFT and degrade it. As a result of its purity, boric acid is commonly used to produce borosilicate TFT glass, which contains between 10-15% B₂O₃.

Boron’s low refractive index allows it to withstand high temperatures as well as thermal shock. Having the ability to be sealed to metal can make it an excellent choice for displays. Despite its lower density than soda-lime glass, it is still capable of breaking into large chunks. Creating flat panels requires a combination of low refractive index and low thermal shock resistance. Televisions rely on it for the technology behind flat panel displays.

Other Uses in Display Screens

Apart from TFT glass, borosilicate glass can also be used as a cover glass for touch screens on mobile devices such as smartphones and tablets. Asahi, for example, produces alkaline-free aluminosilicate glass for use in this market, so not all cover glass contains boron.

A form of borosilicate glass is also used to backlight LCD televisions and PC monitors with cold cathode fluorescent lamps (CCFLs). CCFLs began to be replaced by light-emitting diodes (LEDs) in the late 2000s, which do not use borosilicate glass.

The table below shows a comparison of the two types of products. LEDs offer several advantages over CCFLs, including minor energy consumption (up to 50%), higher brightness, lighter weight, and reduced heat generation.

Comparison of CCFL and LED Screens in Display Backlighting

| Description | CCFL | LED |

|---|---|---|

| Size | Thicker and heavier | Thinner and lighter |

| Cost | Cheper and more cost-effective | Higher initial cost but becomes more affordable as laptop producers switched to LED backlights |

| Power | Higher power consumption and heat generation | Lower power consumption and heat generation |

| Brightness | Lower brightness | Generally higher brightness |

| Finish | Available in matte or glossy | Available in matte or glossy |

| Lifespan | Shorter lifespan | Longer lifespan |

Source: Asahi Company Report, 2015

Reduction in Use of Boron

However, there is a trend to lower usage of boron to reduce the volatile amount of boron during TFT-LCD base plate glass manufacturing. The presence of boron in flat panel display glass can cause an increase in the risk of radiation damage. It is a contaminant in flat panel display glass and will corrode it.

The use of boron in flat panel display glass is the subject of discussion in the industry, and the absence of this metalloid in the mirror makes the technology unreliable. Recently, substitute materials for TFT-LCD glass include rare earth elements such as lanthanum, yttrium, cerium, or Erbium. The rare earth elements are added to reduce the boron content in flat panel display glass.

The presence of boron in flat panel display glass is also a concern among consumers. While boron is harmless in small quantities, it is present in glass at levels that may be hazardous to the environment. The presence of boron in glass in flat-panel displays can also cause colour casts. Although the levels of uranium are low, this element is a significant pollutant that affects the performance of LCD and plasma panels.

Manufacturers of portable battery-operated devices, such as laptop computers, are particularly attracted by these properties. The switch away from borosilicate glass has probably been the greatest in this market.

Manufacturers

TFT glass is primarily produced in Japan, South Korea, Taiwan, Singapore, and China. In addition, the logistical requirements of TFT glass panels require their production to take place mainly in these countries. Currently, only a few suppliers provide glass substrates for TFTs, mainly due to the high-quality requirements and the difficulty of manufacturing.

The largest manufacturer is Corning (including its joint venture with Samsung), but other companies include Asahi Glass, Nippon Electric Glass, and AvanStrate (formerly NH Techno Glass).