Boron the Insulator

Cellulose as an insulator is the most abundant nature polymer in the world. Cellulose-based insulating materials are widely used in electrical equipment including generators, transformers, cables. With the advancement of electrical power technology, electrical equipment has been developing towards high power output and miniaturization. High voltage and high power operating electrical equipment will generate lots of heat.

Boron in use

Fiberglass Insulator or glass wool works in the same way as a wool blanket. It traps air within its thick fiber network to reduce heat loss. Borates are used in fiberglass manufacturing as a fluxing agent. They optimize the production of tiny fibers and lower melting temperatures. This results in extremely fine fibers that are resistant to moisture and compression. The insulation can maintain its loft over time. Borates also increase infrared absorption of glasses fibers which helps improve insulation’s effectiveness.

Cellulose insulators can be made from a variety of organic materials, including cotton and wood. This versatile, lightweight material is used to fill cavities, lofts, and attics with insulation. You can either blow it in or deposit it by hand. Spray-on versions can also be used to cover ceilings and sidewalls.

These materials are usually highly flammable. The addition of BORAT FLAME RETARDANTS allows insulation manufacturers to meet the highest safety standards. Boric acid is a flame-retardant for cellulose insulation. Boric acid is a phenolic compound that can be applied to cellulose materials. It prevents smoldering, promotes the formation of char, which reduces air oxidation, and helps prevent flame.

Weaknesses

However, the poor thermal conductivity of cellulose-based insulating materials will hinder heat dissipation. When the undesirable heat cannot be transferred out of the working electrical equipment timely and effectively, the sharply risen temperature will result in not only reduction of the working efficiency, but also the heat degradation of the internal insulating material or other horrible consequences. Thus, developing cellulosic fiber composites with better heat conduction properties has an impact on the existing cellulose-based insulating materials.

Opportunities

Introducing thermal conducting particles as filler into cellulose-based insulator material is a feasible method to improve its heat conduction performance. The thermal conducting fillers mainly include metals (silver, copper, aluminum, etc), carbonic materials (graphite, carbon nanotube), and inorganic ceramic materials (boron nitride, aluminum nitride, aluminium oxide, etc).

Boron’s superior insulation properties

Boric oxide (B 2O 3) allows for a lower fiberizing temperature and aqueous durability. If the insulation is not protected from atmospheric moisture, it could be damaged by moisture and cause the fibers to become weaker during compression storage. Boric oxide is vital for maintaining a product’s insulation value. It increases infrared absorption, which improves the insulation value of the fibers and reduces the product’s density.

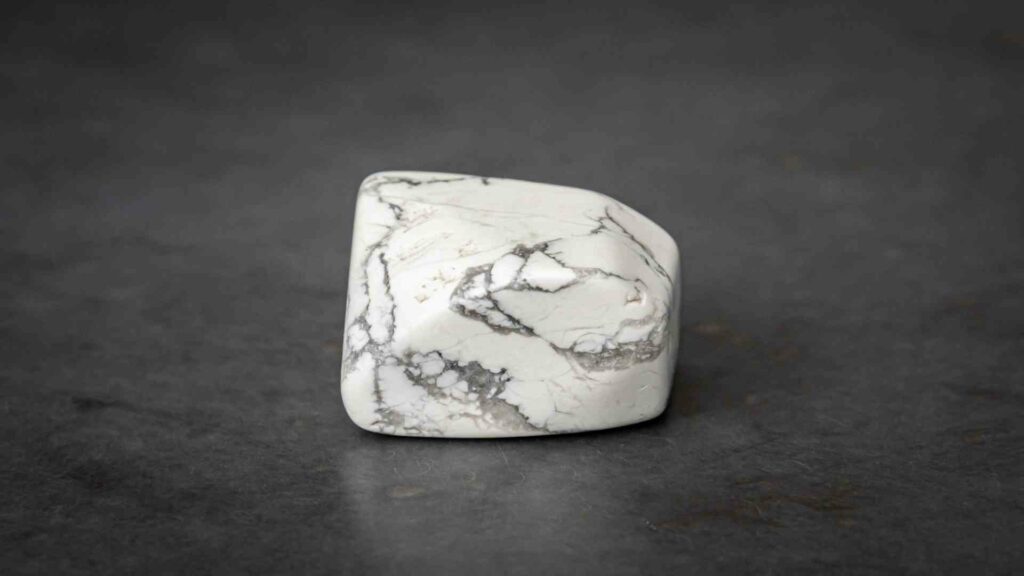

Boron nitride is also under review. Although metals or carbonic materials exhibit ultrahigh thermal conductivity, large amounts of free electrons within these materials inevitably lead to electrical conduction. However, inorganic ceramic materials have desirable high thermal conductivity and excellent electrical insulation properties. Hexagonal boron nitride (h-BN) is a typical III-V compound, which has a similar crystal structure to graphite.

This two-dimensional stratiform crystal structure provides h-BN intrinsic high thermal conductivity. h-BN has the highest thermal conductivity among the ceramic materials. Its in-plane (001) thermal conductivity reaches 180~200 W/(m•k). And h-BN can maintain its original shape at high temperatures because of its extremely low thermal expansion coefficient. In the meantime, h-BN owns a high energy gap of 5.9 eV and exhibits outstanding electrical insulation properties. Based on these merits, h-BN is considered a promising candidate of thermally conductive and electrically insulating filler.

Research

The world is focused on the reduction of carbon emissions and better use of energy. A study entitled “Enhancement of the heat conduction performance of boron nitride/cellulosic fibre insulating composites” looks at borate compounds that offer potentially superior thermal conductivity. Results show the potential for superior performance using boron.

“To further enhance the heat conduction performance of the composites., the 3-aminopropyltr-iethoxysilane(APTES) was added as the modifier to improve the compatibility between BN fillers and cellulosic fibres. And the BN fillers with two different sizes were used to increase the contact area between filler particles. In this case, a higher thermal conductivity of 0.682 W/(m•k) was achieved at BN loading of 41.08 wt%, which corresponds to a thermal conductivity enhancement of about 387% compared with traditional insulating paper. The resultant composites thereby exhibited higher thermal conductivity and better electrically insulation properties.”