Boron Magnets to Power Electric Vehicles

The world is slowly transitioning towards electric vehicles, with the goal of a more sustainable future. Electric powertrains are replacing traditional internal combustion engines. Permanent magnets are an essential component in these new powertrains because they provide constant torque and high efficiency. Permanent boron magnets work well for electric vehicles and have benefits over other types of magnets.

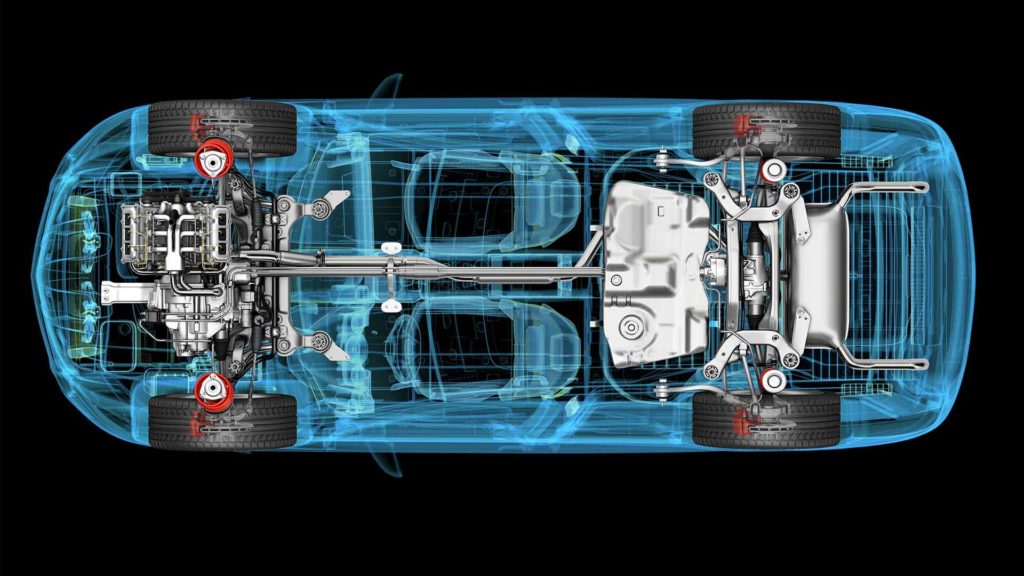

Electric Powertrains are the components that convert power from the battery to a form usable by an electric motor. They are more efficient in their fuel conversion and weight savings due to a lack of moving parts.

Powertrain Boron and Permanent Magnets

How do permanent magnets work?

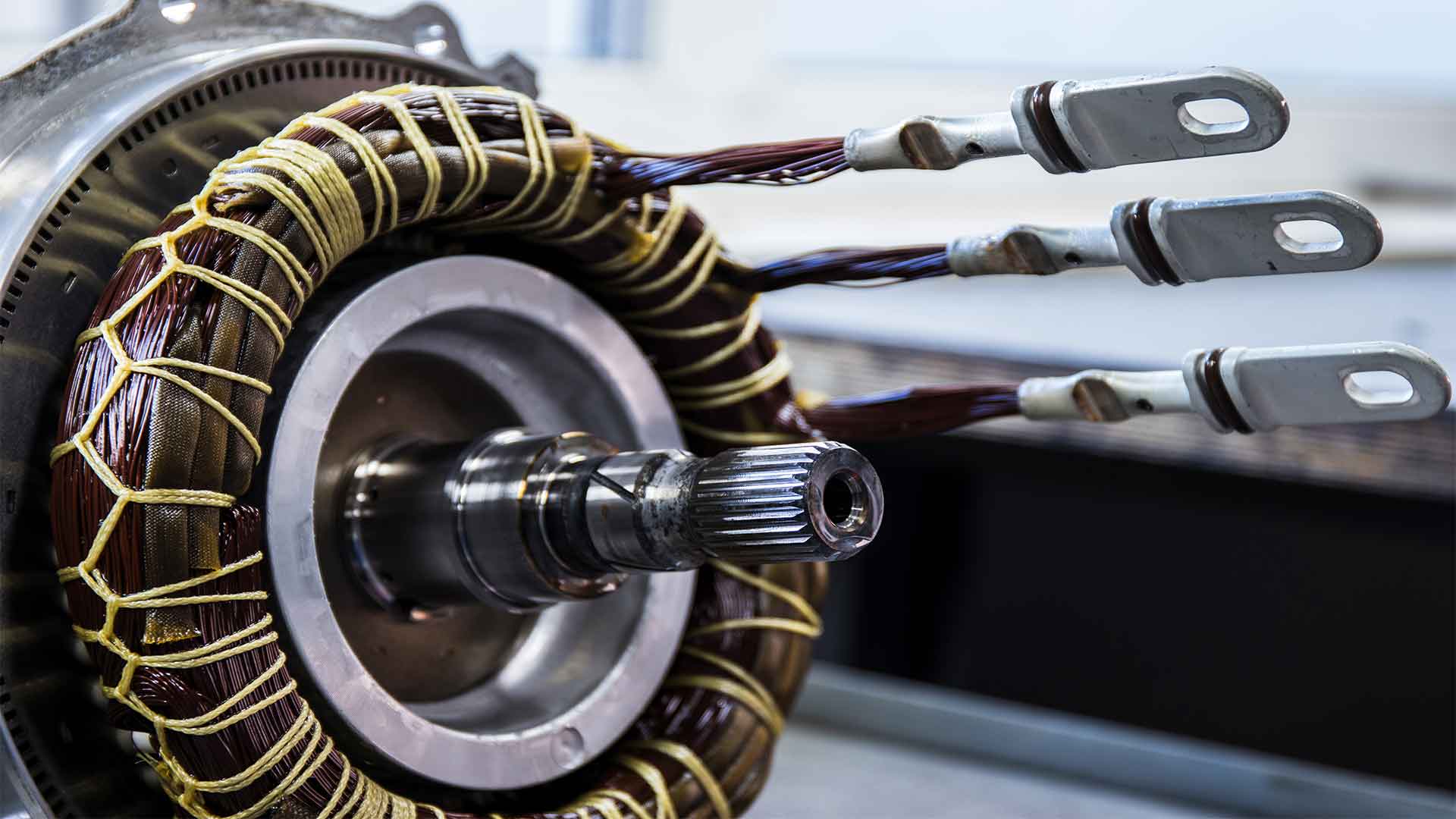

In the electric vehicle powertrain, permanent magnets are placed on both sides of a rotor. The armature coils around these rotors provide energy to spin them in the same direction. This configuration can efficiently produce torque and generate electricity without any moving parts or friction from mechanical seals that use oil as an insulator.

Permanent magnet motors do not require cooling systems typical with electromagnets, which saves weight for Electric Vehicles. They increase efficiency over time because there is no need for heavy power electronics necessary for current AC induction machines. And if permanent magnets were damaged due to external forces (sudden impacts), they are easily replaceable. It is better than needing replacement of entire components like other types of magnetic materials would necessitate.

What are the advantages of Permanent Magnet Motors?

The motor efficiency improves with size. It increases up to a point where there is enough power density by adding more magnets and steel coils.

Permanent magnet motors can reach high speeds (more than 100k rpm). It helps Electric Vehicles for on-demand acceleration necessary in stop-and-go traffic. Or even during simple drag races between electric vehicles.

Permanent magnets have much lower materials costs per watt compared to rare earth electromagnets. They cost lesser than the ones typically used in AC induction machines as well as low-cost maintenance. The lack of moving parts inside a vehicle engine compartment means less frequent replacements over time. No one knows how many miles these motors can last before needing replacements.

Permanent magnet motors will play a significant role in powering electric vehicles in the future. It is because their cost and efficiency continue to rise. But it might take several years for them to become the dominant type of engine due to high upfront costs. Cost per watt could decrease with better production methods that use less rare earth materials or if new processes like cold-casting are developed.

Permanent magnets have greater strength than electromagnets so they tend to require more power management. This means additional electronics components such as a battery charger.

The outlook is good for these types of engines. Usually, it is because there is no shortage of demand from automakers looking into ways to improve fuel economy standards in cars. They also need to comply with tougher emissions regulations. It’ll likely be a few years before permanent magnet engines are the dominant type of engine due to high upfront costs. The cost will eventually come down and these might one day replace traditional gas.

Role of permanent magnets to power electric vehicles

A hybrid electric vehicle is a type of system which combines an internal combustion engine with an electric motor. This combination reduces the demand for petroleum fuels and can reduce greenhouse gas emissions. In turn, it reduces air pollution. Electric vehicles are more than just cars that don’t require gasoline to operate.

They also release zero tailpipe pollutants into the atmosphere. The use of permanent magnets in EV motors relies on many factors including manufacturing costs, performance requirements, durability demands, and maintenance needs. An evolution from electromagnets has led to this new technology as advances in producing high-quality materials.

The advantages of using permanent magnets for electric vehicles include performance, durability, efficiency, and simplicity of design (fewer parts). They offer improved safety because they are more resistant to wear, tear, corrosion, or heat damage. These magnets also create less vibration when the motor is on.

Permanent magnet motors work for high performance and higher efficiency. They are better than other types of electric motors used in vehicles today. For this reason, permanent magnet technologies are adopted by many carmakers as a way to reduce fuel consumption in their hybrid cars.

[Insert image of permanent magnets in electric vehicles]

For example, Toyota’s Prius series uses an electronically controlled “regenerative braking” system. It captures energy from the vehicle slowing down or coming to a complete stop. So it doesn’t need additional power from its battery pack while driving the car.

Why are they better than electromagnets in an electric vehicle?

Permanent magnets are better than electromagnets in electric vehicles for a few reasons. One of the benefits is that they are produced more cheaply. It also means you can provide them at a lower cost, and this has some advantages because it makes EVs cheaper to make as well as being less expensive for consumers.

This new technology can make electric vehicles more affordable and easier to maintain. Hence, it would greatly increase their popularity.

The future for permanent magnets is up in the air as far as any predictions go. However, some trends make it seem like they’re here to stay. Their main limitation is how people design them.

Permanent magnets are useful in both big trucks and small cars. Mainly because they can easily provide enough power to the engine. They are a cost-effective way to power electric vehicles, and thus far they are more efficient.

Electric Vehicles need permanent magnets for their motors so that they can function properly on electricity alone. This is because these cars use an electromagnetic field instead of combustion engines that require pistons or turbines to produce rotational motion.

According to many experts, this type of system consumes less energy than systems powered by fossil fuels such as gasoline. However, it has some challenges due to its expensive battery packs that only last about five years and demagnetizes at high temperatures.

Drawbacks of permanent magnets to power electric vehicles

The high cost of battery packs and the limited lifespan are two major drawbacks of electric vehicles. Heat can demagnetize magnets at high temperatures, such as a hot engine or sitting on top of one.

Role of Boron in permanent magnets to power electric vehicles

Boron is a key component for making permanent magnets. It creates stronger magnetic fields than other types of materials. Permanent magnets use boron to create the necessary poles that can be magnetized and demagnetized over and over again. It helps without losing their original strength. Boron also helps to make permanent magnets more durable. Hence, they can hold up against external forces such as a collision with another vehicle.

Boron is not the only element necessary for making permanent magnets. But it is an integral component of providing strong magnetic fields that are demagnetized over time to create new ones easily.

Final thoughts

The future of transportation may not be so reliant on fossil fuels. Especially, if new developments in the field of electric vehicles continue to progress. Permanent magnets can power an entire fleet or individual vehicle for up to 1 million miles before replacing it with another one. This would significantly reduce fuel consumption and emissions by eliminating the need for expensive battery replacements every few years. It helps many organizations to keep their businesses green and cleaner.