Future with Borosilicate Glass

Borosilicate glass is a type of glass with unique properties that make it perfect for a variety of applications. This material is made with boron and silicon, two materials that are known for their durability. When combined, they create a glass that is resistant to thermal shock and chemical corrosion.

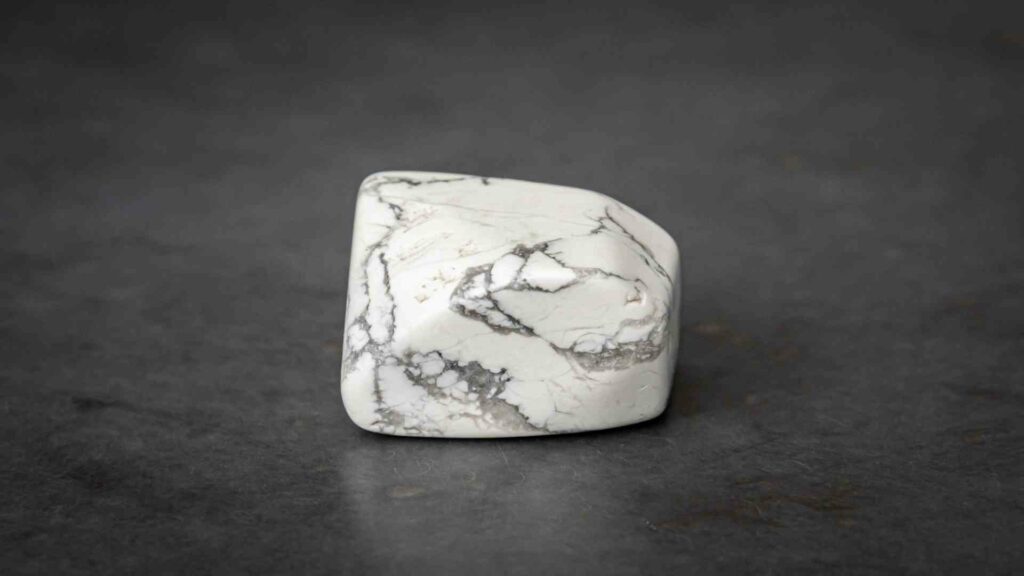

Borosilicate Glass

History of Borosilicate Glass

Borosilicate glass is a family of glasses with remarkable properties, first developed by Otto Schott in Jena, Germany during the late 19th century. Before long, it had become known solely as “Jena glass”. By 1915 Corning Glass Works unveiled their now-famous Pyrex brand; since that time borosilicate has been indelibly associated with this name across much of the English-speaking world. Today’s borosilicate families have different members suited to an array of applications making them truly versatile materials for modern industry and commerce.

Uses of Borosilicate Glass

Medical Fields

Health and medical services are used in a variety of ways, such as surgical instruments and equipment for laboratories. It is also used in the manufacture of high-quality implantable medical devices.

Electrical Devices

In electronics is used as electrical insulator, such as in high-voltage transmission lines.

Space Exploration

Borosilicate glass is used in space to ensure that instruments and equipment withstand the harsh conditions of being up there for potentially years on end.

Cookware

It is used for cookware because it can withstand high temperatures. This makes it an ideal material to use when cooking acidic foods such as tomatoes and wine, which could potentially damage other types of materials. Borosilicate cups or bowls can be used for hot liquids without fear of it shattering or cracking from heat. It’s also been found that it helps prevent food from sticking to the pan.

Lighting Instruments

It is used in high-quality flashlights which helps in creating a beam of light with the desired color or shade. This also helps in increasing the light transmittance which is much better compared to plastics and lower-quality glass.

Optics and Lenses

It is widely used in optics and lenses because of its clarity and durability.

Incandescent Bulbs

Borosilicate glass is used in household lighting and other standard lamps as well as being one of the major components that make up incandescent light bulbs.

Lab Equipment

Beakers, flasks, and test tubes are all examples of lab equipment made from borosilicate glass. Due to its thermal properties and chemical stability, it proves to be excellent in this.

Why is Borosilicate Better than Regular Glass?

Borosilicate glass is a type of safety glass that has gained popularity in recent years, with more and more people discovering the many fascinating uses it can be put to. The main feature that has helped this material gain worldwide recognition is its high resistance to thermal shock and chemical corrosion.

The best part about borosilicate glass is that it can withstand just about anything! Have you ever broken a drinking glass? If so, the odds are good that it wasn’t made out of this incredible material. It has an incredibly low coefficient of thermal expansion which translates to its ability to be used for high-temperature applications and still maintain its shape without developing stress points or cracks over time. It is thin and durable, microwave and dishwasher-safe while regular glass isn’t.

It is made from a silica mix, sodium oxide, boron trioxide, and other additives. The ingredients go through some heat treatments to promote chemical reactions that will produce an extremely strong type of glass with low thermal expansion rates.

It has exceptional mechanical strength, thermal properties, and chemical stability. It can improve the type of glass that could be heated and cooled without breaking or forming stress-induced flaws.

Also, improved manufacturing processes have made it more widely available and cost-effective for many purposes.

Why Choose Borosilicate Glass Over Soda-Lime Glass?

- It is made from silica and boric acid with small amounts of sodium or potassium oxide to lower its melting point so that it can be molded into desired shapes while soda-lime glass is the “original” glass. It is made with sodium carbonate and calcium oxide which can not be considered very much in getting desired shapes that too forms vacuum vessels like the borosilicate glass.

- The coefficient of soda-lime glass is more than double that of borosilicate glass, which means that it expands more than twice as fast when exposed to heat and will break very quickly.

- It has a much higher proportion of silicon dioxide in comparison to regular soda-lime glass (80% vs. 69%), which makes it even less susceptible to fractures.

- In terms of temperature, the maximum thermal shock range (the difference in temperatures it can withstand) of borosilicate glass is 170°C, which is about 340° Fahrenheit. This is why you can take this glass (and some bakeware like Pyrex more on this below) out from the oven and run cold water over it without shattering the glass.

- It is so resistant to chemicals, that it is even used to store nuclear waste. The boron in the glass makes it less soluble, preventing any unwanted materials from leaching into the glass, or the other way around. In terms of overall performance, borosilicate glass is far superior to regular glass.

- Here’s an example, CorningWare or Pyrex bakeware exploding was not a matter of worrying until borosilicate glass was used in its manufacture, which is more resistant to breakage when subjected to extreme shifts in temperature and had a much thinner width. Modern Pyrex is made of tempered soda-lime glass, which can shatter when subjected to extreme heat.

- Improved manufacturing processes have led many manufacturers to use borosilicate in products such as cookware and lab equipment instead of the traditional soda-lime glass which is not as reliable to use considering its properties as compared to borosilicate glass.