FEAM Securing Global Supplies and Decarbonizing the Economy

FEAM, 5E Advanced Materials, Inc., focuses on providing secure and reliable supplies of critical materials that empower global decarbonization and create a better future for generations.

FEAM

About FEAM

FEAM has a great story to tell. It addresses the need for a domestic supply of critical materials with a focus on advancing the development of renewable energy technology and supporting decarbonization and sustainability efforts.

While lithium comes first to mind when discussing the above, 5E Advanced Materials is focused on boron. Boron is a rare earth that doesn’t get the attention it deserves. It is used in a wide range of everyday items, from fertilizers and food to screens on smartphones and even in permanent magnets and motors.

It’s a versatile micronutrient that helps us with our day-to-day needs, yet we often forget about it in favor of rare earth elements, which are more widely publicized. Boron’s applications, however, are vast and continue to grow as technology advances its properties for newer, better products.

FEAM believes that boron could be the next big player in the renewable energy industry. Its team is constantly researching and exploring new ways to utilize this element, which is abundant in nature and has multiple applications for energy storage.

For now, the company has developed exciting technologies using boron’s unique properties to provide safe, clean, renewable energy solutions that will reduce reliance on fossil fuels and help move the planet toward a sustainable future. With 5E leading the charge, boron might be the next lithium.

How does FEAM Plan to Mine Boron?

FEAM is dedicated to assisting mining-friendly communities in growing and prospering. Its boron project in Southern California is an excellent example of this commitment in action – it’s situated right in the Mojave Desert. 5E will not only mine materials here but also process them locally and sell them domestically without a focus on exports. This fits into the domestic supply megatrend, supported by the current administration under President Biden.

In-situ Leaching

5E is spearheading the way for sustainable mineral extraction with its innovative technology. This is underground mineral extraction, also known as in-situ leaching, accomplished by drilling small injection and extraction wells with diameters of 6 to 8 inches.

In-situ leaching involves infusing heavily diluted hydrochloric acid into the ore body. It is enclosed in a casing. It’s infused into the ore body and disperses completely. When it is drawn back, it is known as a pregnant leach solution containing all the minerals. The minerals are then crystallized and formed into boric acid, lithium carbonate, and some gypsum, ready to be sold in the market.

Since boric acid is the final main product, this is known as a boric acid production facility. This entire process minimizes environmental disruption above ground and uses minimal energy, resulting in a lower carbon footprint for everyone. It also provides high-skilled employment, which will help the local economy.

FEAM has the world’s only permitted boron projects. When constructing a project in the desert, they have state permits for air and, more importantly, water.

Is FEAM’s Sustainable Mining Technology the Answer to Decarbonization?

FEAM is pioneering decarbonization technologies to reduce the carbon footprint of mining operations. It also produces boric acid and its derivatives, which have many applications in decarbonization technologies.

This includes capturing and storing carbon dioxide, constructing blades for wind turbines, borosilicate glass for solar panels, and manufacturing lithium-ion batteries for electric vehicles.

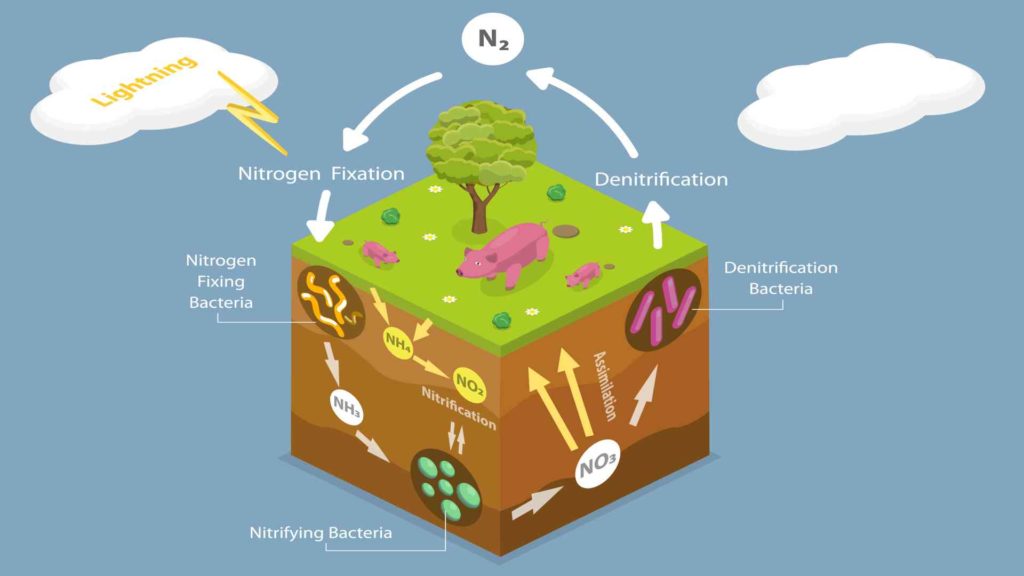

Furthermore, boric acid also serves as an important component in soil fertility programs; its presence provides a nutrient source for beneficial microbes that promote healthy soil and greater crop yields.

Boron compounds can also be used for heat transfer applications, allowing more efficient energy use in industrial processes such as steel-making and cement production. As the world looks towards methods to combat climate change, boron compound usage is becoming increasingly important in offering decarbonization technologies.

5E and Its Partnerships for Sustainable Operations

1. Partnership with Corning Inc. is a major milestone for FEAM as it further expands its product portfolio and solidifies its position in the boron specialty materials market. Combining expertise and resources from both companies will offer further research and development opportunities, including more efficient production, improved performance, and new uses for these materials.

2. Bluescape Energy Partners’ investment in FEAM is a significant step forward for the boron and lithium company’s exploration stage. The $60 million portfolio investment of senior secured notes adjustable into FEAM common stock allows the company to expand its research and development efforts, opening up new possibilities in its manufacturing process.

3. The 5E and Boston College research agreement is part of the company’s ongoing commitment to developing affordable and reliable renewable energy solutions. With this agreement, 5E hopes to create a new generation of solar energy systems that are more efficient and cost-effective than currently available.

Boston College has already made significant strides in boron materials research, leading to breakthrough advancements in developing solar cells at smaller sizes with higher efficiency rates. This research collaboration between 5E and Boston College will build on these accomplishments by further exploring how boron-based materials can be used for more effective solar power storage and conversion processes.

The Secret Behind the Company Name

At 5E Advanced Materials, they believe in product development and innovation. They are developing a portfolio of advanced materials products to last over the entire 50-year mine life. Their teams bring decades of experience and expertise, coupled with their commercial partners, to ensure that all stakeholders benefit from this endeavor.

Every step taken is focused on driving maximum value for shareholders while creating innovative solutions to meet customer needs, and great pride is taken in efforts toward innovation and sustainability.

5E’s Future Plans

From a commercial and operational standpoint, FEAM is constructing a small-scale boron facility (SSBF) that is reported to be commissioned within the first quarter of 2023.

With that, 5e can start accessing production in Q2 and have a product on the market soon. Several cycles of tests would run to determine flow rates, head grades, and other important metrics. There will also be many catalysts from the commercial operations perspective.

FEAM is currently engaged in significant conversations with a range of customers that will assist them in moving to the next step and be part of the company’s evolution.