Boron Rocket Fuel

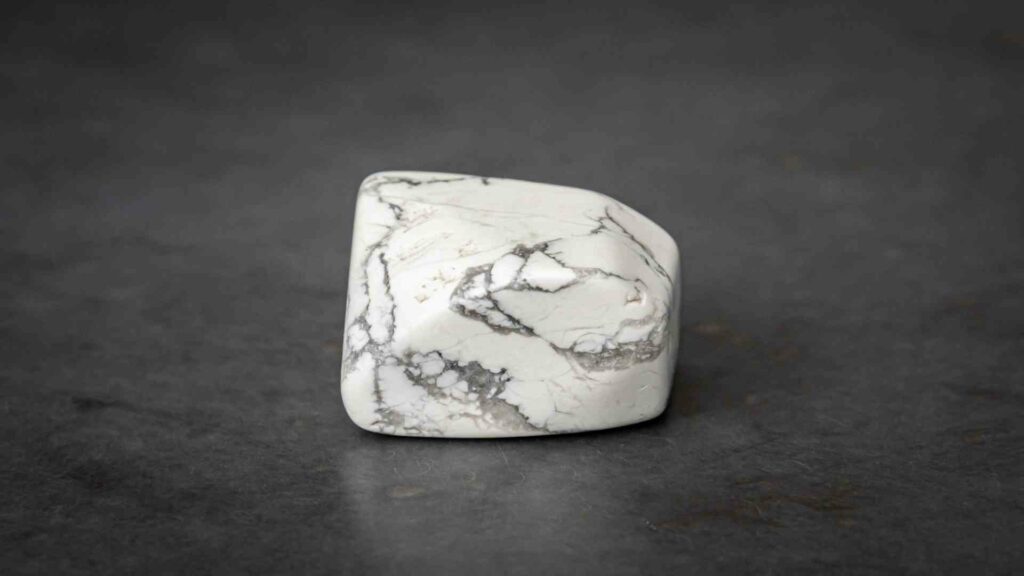

Boron Rocket Fuel: Boron has a high intrinsic energy density. It is inexpensive, plentiful, and stable, making it a good choice for solid rocket fuels and an additive for jet fuels to increase their energy output. However, the oxide shell and its impurities make boron unreliable at the ignition point. Research is ongoing into overcoming these impurities so that boron fuel may be used more widely in space travel.

Boron Rocket Fuel

Benefits of Boron in Rocket Fuel

Herman Krier, Richard W. Kritzer, Professor of Mechanical and Industrial Engineering at the U. of I, stated that rocket performance is determined by energy per pound of propellant. If the rocket can carry less propellant, it has more payload.

Liquid fuels or oxidizers offer more energy per pound than solid propellants. However, liquids must be cryogenically cooled, which adds to their cost and make them difficult to store. Solid propellants can be safely stored for many years, even in harsh environments. They are also cheaper to produce.

Solid-fueled rockets today use propellants from the 1960s and 1970s. Krier stated that these materials are safe and reliable but not very energetic. “New propellants are likely to contain high-energetic metals like magnesium and boron,” Krier said that boron is a desirable additive for rocket fuels because of its low molecular mass and high combustion energy.

Specifically speaking, the bipropellent, composed of boron & nitrogen, produces large quantities of hot gases in a short time. These gases are helpful for many purposes, including providing the thrust necessary for rockets.

Additionally, boron carbide has a high combustion enthalpy. Boron carbide can be easily manufactured using well-known electric furnace techniques. It is also readily available at a low cost. These boron carbide-solid oxidizing agent mixtures can be stored for as long as one wants without deterioration or danger of premature ignition. These mixtures are so stable that an igniter is needed to start the reaction between their components.

Boron Compounds Used in Rocket Fuel

Boron carbide has been considered a good fuel component for solid rocket propellant compositions. Rocket propulsion can also be achieved using a bipropellant made of boron and nitrogen compounds. A nitrogen-containing combination that is only composed of carbon, hydrogen, and nitrogen is combined with a boron-containing compound composed of carbon, hydrogen, and carbon.

At least one reactant needs to contain hydrogen, and at least one reactant needs to contain carbon. In a 2015 study, a composition consisting of 80% polytetrafluoroethylene and 20% boron (by weight) was considered a potential high-density solid fuel mixture for mixed hybrid rocket propulsive applications.

Challenges & Research Related to Boron Combustion

There has been extensive research on boron as solid rocket fuel and as an additive to jet fuels. However, this propellant has been difficult to tame due to its variable and complex combustion behaviour.

Alla Pivkina, Nikita Muravyev, and colleagues from the Semenov Federal Research Center for Chemical Physics Moscow have conducted a series to explain why this is. Pivkina says that boron particles cannot be ignited easily because the solid boron core has an oxide shell, which acts as a protective coating, delaying or preventing ignition and combustion.

Figuring Out the Thermal Behaviour

The researchers discovered that different boron powders have different shell compositions because of various impurities such as magnesium and aluminum, and their oxides, during production.

Pivkina says, “We demonstrated that boron particles with differing impurities within the oxide shell have significantly changed thermal behaviour.” The researchers reported their findings in the journal Combustion Explosion and Shock Waves. They have now shown that impurities can either hinder or enhance combustion performance by thermal analysis of the powder.

Pivkina also reported that they found that aluminium and magnesium oxide impurities reduced evaporation of the boron oxide and thus decreased the activity of boron ignition. In contrast, magnesium fluoride had the opposite effect.

The oxide layer goes through melting, dehydration, and evaporation during heating. Each step takes place at a different temperature depending upon the presence of impurities. Researchers discovered that magnesium and aluminum undergo metallic thermite reactions with boron oxide, which can cause problems with combustion and leave unwanted oxide residues.

However, magnesium fluoride forms boron fluoride gas at 1000 °C. This promotes the evaporation and activation of the boron core at around 1300 °C, which helps reduce troublesome ignition delay.

Pivkina concluded that they are currently investigating a variety of binders to optimize the combustion of boron-based fuels. “The results will open up new avenues for the ignition and combustion of boron particles in energetic formulations.”

Fluorine For Enhancing Boron Combustion

Another group of researchers experimented and studied how fluorine can enhance boron combustion. They considered the possibility that fluorine (the most reactive element) can attack and remove the oxide coating. This would reduce the ignition time and increase the rate of combustion.

Krier and his coworkers–Martin Spalding, a doctoral candidate in aeronautical and astronautical engineering, and Rodney Burton, an aerospace and astronautical engineering professor–used the U. of I. High-Pressure Combustion Laboratory’s 12-meter shock tube to study the effects of fluorine on the combustion of boron.

Boron particles were ignited at high temperatures and pressures in atmospheres containing argon, oxygen, and varying amounts of fluorine. Time-resolved spectra of the burning particles were obtained using a streak camera to record the output of a sensitive spectrometer.

Krier stated that “spectral fingerprints of reacting molecules allowed for us to determine the time it took before reactions started, identify specific reactions, and measure the time it took for particles to burn.”

Krier stated that when a small amount of fluorine was added to the shock tube, there was a reduction in the ignition delay and total combustion time. He remarked, “Now that the chemical models have been verified, we will seek out a safe and efficient way to incorporate fluorine in the solid propellant.”