Industrial Decarbonization and Boron

Industrial decarbonization is a critical step in the fight against climate change, and boron plays an essential role in this process. It helps reduces emissions from power plants and factories, on a quest for a more sustainable future.

Industrial Decarbonization

Industrial Decarbonization

As the United States works to decarbonize its economy and achieve net-zero carbon emissions by 2050, players in multiple industrial sectors need to play a critical role. Industrial decarbonization is lowering or eliminating GHG emissions from all fields of industry without risking the sector’s vital contributions to the country’s financial competitiveness and prosperity.

Currently, the industrial sector is responsible for 30% of domestic GHG emissions. Decarbonizing this sector is crucial to addressing our climate goals and ensuring our planet’s health in the future.

Sources and Pollutants of Industrial Emissions

Industrial emissions come from various sources, ranging from smokestacks and tailpipes to landfills and agricultural operations. The primary pollutants emitted by industry are particulate matter, sulfur dioxide, nitrogen oxides, carbon monoxide, volatile organic compounds (VOCs), and heavy metals.

Particulate matter is a combination of solid particles and liquid droplets suspended in the atmosphere. It can be emitted directly into the atmosphere from construction activities, unpaved roads, quarrying operations, and coal-fired power plants. Industrial processes that involve grinding, crushing, or conveying materials can also generate large amounts of particulate matter.

Sulfur dioxide is a gas produced when materials containing sulfur are burnt. It is emitted from coal-fired power plants, oil refineries, and smelters.

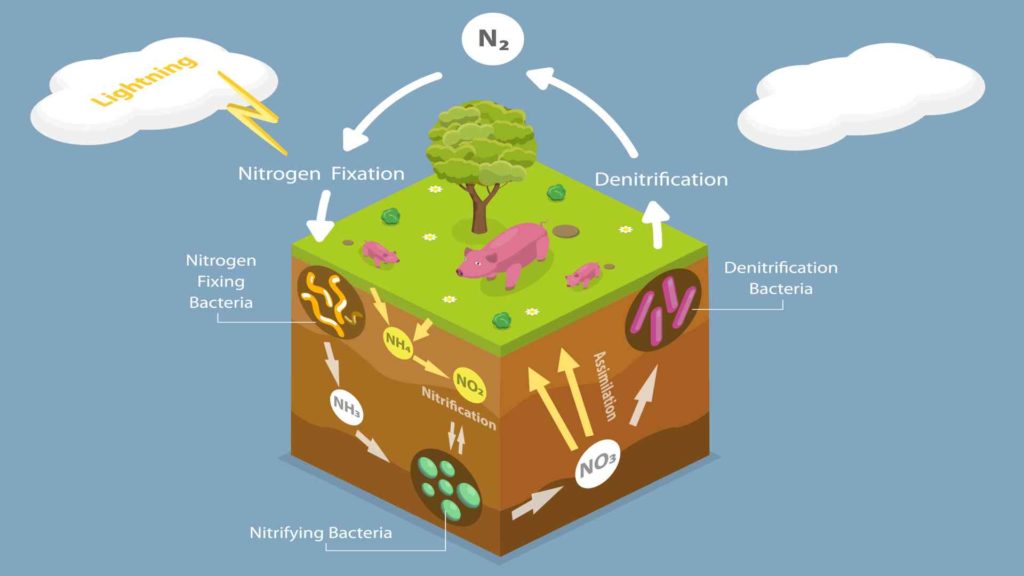

Nitrogen oxides are a group of gases produced when nitrogen-containing materials are burned. They are emitted from cars, trucks, power plants, and industrial boilers.

Carbon monoxide is a colorless, odorless gas produced when carbon-containing materials are burned. It is emitted from cars and trucks, as well as from industrial facilities such as chemical plants and steel mills.

Volatile organic compounds (VOCs) are a group of chemicals that evaporate quickly at room temperature. They are emitted from various sources, including solvent use in the manufacturing process, paint stripping, and dry cleaning.

Heavy metals are metallic elements that can cause health problems if inhaled or ingested. They are emitted from various industrial sources, including metal smelters, coal-fired power plants, and hazardous waste sites.

Impact on Human Health

Particulate matter, sulfur dioxide, nitrogen oxides, carbon monoxide, volatile organic compounds (VOCs), and heavy metals are all types of industrial emissions that can negatively impact human health. Inhalation of particulate matter can cause respiratory problems, while exposure to sulfur dioxide and nitrogen oxides can irritate the lungs and airways.

Carbon monoxide exposure can lead to headaches and dizziness, while VOCs can cause various health problems, including cancer.

Heavy metal exposure can damage the nervous system and kidneys. It is important to limit exposure to these pollutants by avoiding areas with high levels of industrial emissions and wearing proper protective gear when working in industries that emit these pollutants.

Industries that Need Decarbonization

The five greatest energy-intensive industries are:

- Chemical production – Responsible for 20% of industrial CO2 emissions and 24% of industrial energy usage.

- Petroleum refining – Responsible for 17% of industrial CO2 emissions and 15% of industrial energy usage.

- Iron and steel manufacturing – Responsible for 7% of industrial CO2 emissions and 5% of industrial energy usage.

- Food and beverage manufacturing – Responsible for 6% of industrial CO2 emissions and 5% of industrial energy usage.

- Cement production – Responsible for 2% of industrial CO2 emissions and 1% of industrial energy usage.

Boron’s Role in Industrial Decarbonization

Boron can be a major player in decarbonizing these industries by helping to replace more carbon-intensive materials and processes. Boron’s ability to reduce greenhouse gas emissions and improve energy efficiency is an essential part of the decarbonization process. For example,

- Boron is used as a catalyst in the chemical industry in producing plastics and other synthetic materials. It is also used for manufacturing detergents, cosmetics, and pharmaceuticals. In addition, boron compounds are also used as flame retardants, corrosion inhibitors, and water treatment chemicals.

- In petroleum refining, boron helps to remove impurities from crude oil and improves the efficiency of refinery operations.

- In iron and steel manufacturing, boron is added to molten steel to remove oxygen and other impurities and also helps to improve the strength and hardness of the final product.

- In food and beverage manufacturing, boron is used as a food additive. It is added to foods to improve their flavor or texture or to help preserve them. Boron can also be used to create colors in food products.

- In cement production, the role of boron in cement production is twofold. First, boron slows down the hydration reaction of cement, which is the process that causes concrete to harden. This allows concrete to be poured and set at a faster rate, which is important for construction projects that must complete quickly. Second, boron makes concrete more resistant to water damage and weathering. This means that buildings made with concrete will last longer and require less maintenance over time.

Techniques for Achieving Industrial Decarbonization

Accelerating industrial decarbonization in the industrial sector is essential for climate change mitigation. Four key strategies can be used to achieve this: energy efficiency, industrial electrification, low-carbon fuels, Feedstocks and Energy Sources (LCFFES), and Carbon Capture, Utilization, and Storage (CCUS).

Energy efficiency measures reduce the energy required to produce a given output, thereby improving decarbonization. Methods used through energy efficiency are –

- Strategic energy management to improve the overall performance of industrial processes.

- Thermal heat management and optimization from manufacturing process heating, boilers, and combined heat and power (CHP) sources

- Smart manufacturing and advanced analytics to boost manufacturing energy productivity

Industrial electrification refers to using electricity instead of fossil fuels in industrial processes. Here are some examples:

- Process heat electrification via induction, radiant heating, or advanced heat pumps

- Electrification of high-temperature range systems found in iron, steel, and cement manufacturing

- Using electrochemical processes instead of thermal ones

Low-carbon fuels and feedstocks emit less carbon dioxide when combusted than traditional fossil fuels. These include

- Process development for fuel flexibility

- The incorporation of hydrogen fuels and feedstocks into industrial uses.

- The utilization of biofuels and bio feedstocks.

Carbon capture, utilization, and storage (CCUS) technology capture carbon dioxide emissions from industrial facilities and stores them underground, preventing them from entering the atmosphere. This strategy’s components include:

- Post-combustion chemical absorption of CO2

- production and construction of advanced CO2 capture materials to enhance efficiency and reduce capture costs

- Process development to use captured CO2 to create new materials

FEAM Plans to Lead Borate Extraction and Processing For Industrial Decarbonization

New entrants to the boron supply market such as 5E are positioned to provide materials to manage decarbonization with boric acid as a critical player in energy transformations. 5E Advanced Materials (NASDAQ: FEAM), also known as American Pacific Borates, is involved in the extraction and processing of global borates with longer-term, downstream refinement adaptability, directed by a primary focus on boric acid (H3BO3) – a key source in downstream boron refinement into products integrated with high-end NdFeB magnetics for use in EV powertrains and other EV implementations, wind power generation, and other appealing decarbonization.

5E’s initial output emphasis for Fort Cady, boric acid, is an industry primarily dominated by a duopolistic structure guided by Eti Maden, which supplies 60% – 65% of global boric acid from Turkey, and Rio Tinto, which provides an additional 20% -25% from an aging open-pit resource in Southern California.